|

Title: |

1905 Article-Badger State Machine Co., Rip Saw Table |

|

Source: |

Wood Craft, Oct 1905, pg. 49 |

|

Insert Date: |

9/25/2015 11:05:11 AM |

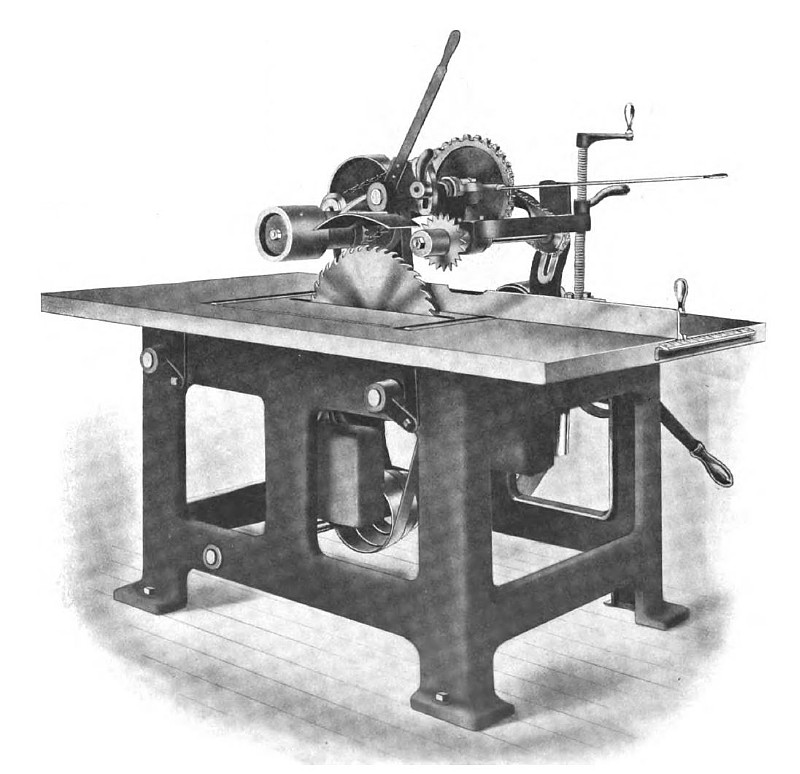

The Badger State Rip-saw Table

The frame is cast in one piece and is wide and very heavy. There are long, self-oiling boxes for the saw arbor and a strong double brace to the bearing outside the pulley. All boxes are lined with best Babbitt metal. The table is all iron, heavily ribbed and is 37 inches wide and 5 feet 8 inches long. There is an opening around the saw into which an iron detachable plate or throat piece is accurately fitted. This plate is taken out when saws are changed, avoiding the lifting of the table. This also allows several saws on the arbor at the same time, if desired, for ripping small strips. Friction rollers are placed in table before and after saw.

A quick lever table raising attachment is applied to this line of saw frames It counterbalances the table top on supports from two shafts with heavy vertical guides and by a single lever the top is instantly raised or lowered horizontally. This is valuable where various thicknesses are cut, the table can be instantly adjusted to give the proper height and thus secure easier ripping and save wear or heating of the saws.

The feed works on the table arc of powerful yet simple design without spur or bevel gears. The heavy link chain on the sprocket wheels is durable, and if worn is readily replaced at little cost. The feeding-in spindle has a set of collars to take extra spurs for gang ripping, also a fine cross adjustment to accurately bring the feed spur into the line of the saw kerf. Over the saw there is a spring steel guard which, with the front and the rear feeds, protects the operator. The entire feed works adjust automatically to the varying thickness of stock. The feed can be stopped or started, the feed works raised or lowered, and the table raised or lowered by the operator without leaving his position at the front of the machine. The out-feeding device regularly carries a driven smooth roller, but corrugated or sectional rollers can be supplied. This out-feed adds to the power of feed, carries all pieces beyond the saws, and as a safety device will protect hundreds from injury. The safety features of the machine include a release clutch, which instantly stops the feed mechanism. The two feeds are strongly driven and cone pulleys on the lower countershaft give any desired rate of feed. If the machine is needed for a plain saw bench at any time the entire feed works, pivoted on a swivel joint, may be swung upward and to one side, leaving the table clear. If desired the feed works may be removed entirely from table by loosening one screw.

The saw gage is moved, locked and released by one lever. It has a pointer following a bronze ruler, so placed as to have the figures clear and free from dust.

The fence or guide is accurately adjustable to line with the saw or relieve it when necessary.

This machine will take an 18 or 20 inch saw and rip three or four inches regularly or, if required, six inches thick, also 16 or 17 inches wide. The saw arbor is of fine grade steel; it is 1¾ inches in bearings and 1¼ inches where the saws are placed. The saw arbor hearings are extra-long and are self-oiling. The pulley on saw arbor is 8 inches in diameter and has 7½-inch face. The feed works are powerful and will give three changes of feed, say from 85 to 200 feet per minute. Saw arbor speed should be 3,100 revolutions for a 14-inch saw or 2,800 revolutions for an 18-inch saw.

This self-feed rip-saw table is made by the Badger State Machine Company of Janesville, Wis. |

|

1905 Badger State Machine Co., Rip Saw Table

1905 Badger State Machine Co., Rip Saw Table

|

|