|

Title: |

1880 Article-H. B. Smith Machine Co., 10 inch Moulding Machine |

|

Source: |

American Machinist, 29 May 1880, pg. 2 |

|

Insert Date: |

7/11/2015 7:35:22 PM |

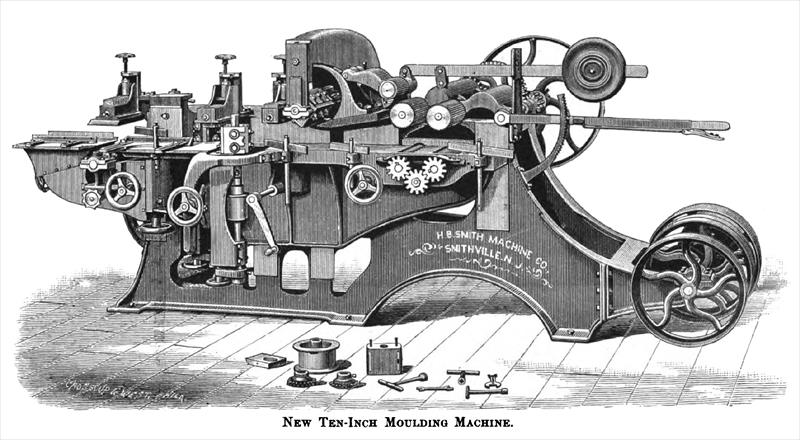

New Ten-Inch Moulding Machine

The moulding machine, herewith illustrated, is of a new and improved style. Its manufacturers have aimed to embody in this machine all the best features that experience and skill could suggest. It is intended to meet the wants of car shops and large moulding establishments, and is capable of cutting any kind of moulding not exceeding ten inches in width and four inches in depth. It will also dress on four sides, flooring and sheathing, planing and matching, up to ten inches wide.

The table drops twelve inches for jointing door rails, etc., thus enabling the machine to plane on two sides timber not exceeding in dimensions 10 x 12 inches. The vertical screw for adjusting the table is operated by a horizontal shaft in the front, geared so as to gain power and is convenient of access. In addition to the support afforded by the single adjusting screw and long gibbed bearing, the table is firmly clamped to the frame near each end by two powerful screw bolts, which hold it perfectly steady in any desired position. A rigid outside bearing is provided and so arranged as to leave the upper head accessible from all points. This bearing is never disturbed while raising or lowering the table, and its position upon the shaft is not changed by adjustments of the upper headstock.

Provision is made for adjusting this headstock from the front of the machine, instead of the rear, as heretofore.

That portion of the table carrying the under cylinder is vertically adjustable by means of a single screw. The under cutter is adjustable endwise and is freely accessible. The end beyond the under cutter is also adjustable. Each of the side heads are adjustable to or from the table by means of a single screw; they are also adjustable up and down, and may both be set at any desired angle.

The machine is provided with the necessary springs and the three pressure bars, one of which is placed between the upper and the outside heads. These latter are arranged with adjustable sections, adapting them for holding mouldings of any shape, or plain bars may be applied for surfacing only. All speeded shafts are of steel and run in boxes lined with the best Babbitt metal. The cutter heads are all of moulded steel and slotted to carry four knives, except the under head, which is furnished with two slots only, unless otherwise ordered.

The feeding mechanism is of improved construction, consisting of two upper and two lower rolls, all driven, and is claimed to be the most powerful of any ever applied to a similar machine. The two upper rolls are fluted and heavily weighted. Smith's patent spur feed rolls are also furnished. Four rates of feed are provided, viz.: 20, 30, 36, and 52 feet a minute. The machine weighs about 4,500 lbs. The manufacturers are H. B. Smith Machine Co., Smithville, N. J. |

|

1880 H. B. Smith Machine Co., 10 inch Moulding Machine

1880 H. B. Smith Machine Co., 10 inch Moulding Machine

|

|