|

Title: |

1880 Article-W. F. & John Barnes Co., Foot-Powered Former |

|

Source: |

American Machinist, 24 Apr 1880, pg. 3 |

|

Insert Date: |

7/7/2015 9:03:30 PM |

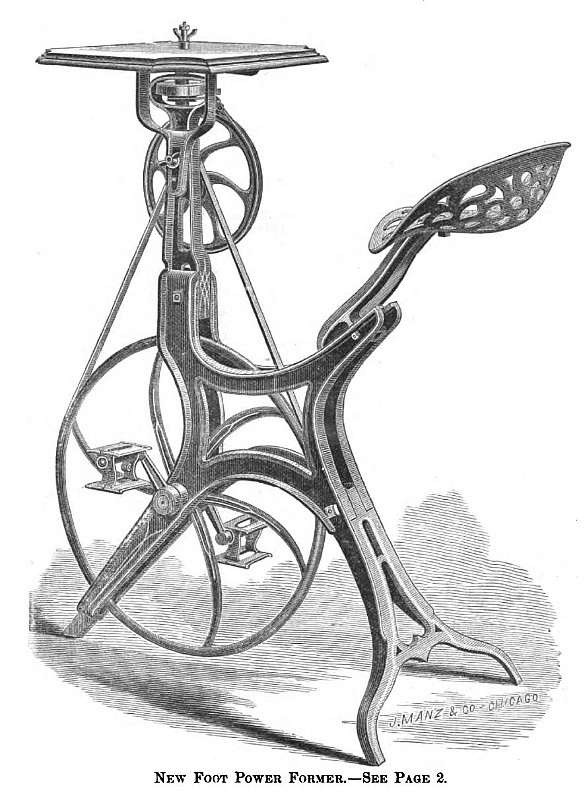

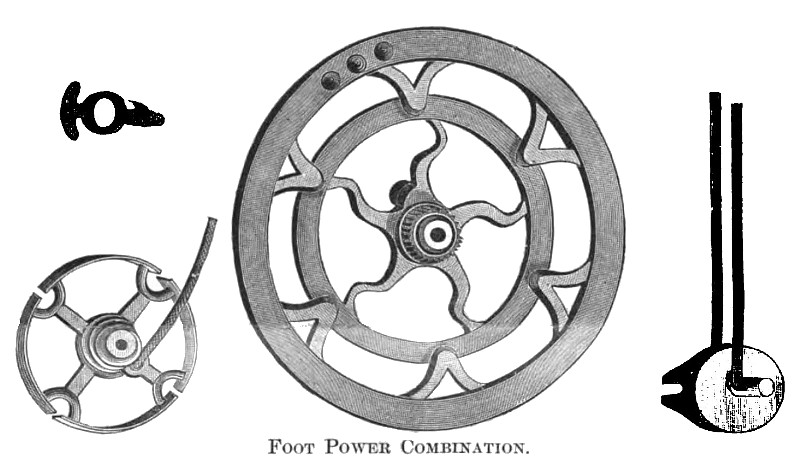

Foot Power Forming Machine and Attachments

On this page and the one opposite, we illustrate a foot power combination, a foot power former, and the knives and fluting attachment belonging to the latter, which possess some novel and valuable features. The parts of the foot power combination are shown detached, also in the machine itself. The large wheel is the only revolving wheel. The other oscillates about once around, and is termed a "take up" wheel. An oscillating thimble is used with two straps, which wind on and off by the action of the treadle-spring and wheel. A dog connects motion from thimble to the wheel.

In operation, the thimble is caused to oscillate by the two straps winding on and off. One is attached to the treadle, the other to the small wheel. This wheel is acted upon by the treadle-spring, which re-winds it, and thus causes the treadle-strap to rewind upon thimble. The thimble carries the dog hack and forth, which engages in large wheel in its forward motion, and without checking its speed, runs back idle for a fresh hold. By this simple arrangement, and with the effort of an ordinary walk, the large wheel can be driven at the rate of from 800 to 1200 revolutions per minute.

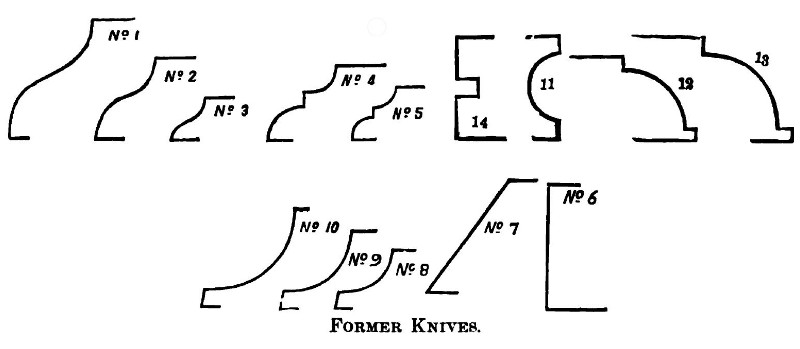

The foot power former represented on the opposite page is designed for moulding edges of brackets, scroll work, panel work, regular and irregular, mouldings of all styles up to 7/8 of an inch. The speed of the knives is from forty to forty-five hundred revolutions per minute. The "velocipede foot power" is used with the combination above described. By means of this arrangement (the operation of which will be readily seen by reference to the cut), the knives are, at the will of the operator, caused to rotate in either direction that the grain of the wood may require, thus avoiding all complicated devices for reversing motion usually employed on single spindle formers. The great speed of the knives insures rapid and smooth work. Articles that look very plain can be made elegant and costly in appearance by the rapid and accurate work of this machine. Knives are furnished for the machine with edges like those shown in the cut.

The fluting attachment is used for fluting table legs and like objects. A, shows the edge of the pattern, the shape of which regulates the cut on the leg lengthwise.

The index-plate is spaced to make several divisions of a circle, and is regulated by the snap-latch at B. C, is a screw-center with which the leg is fastened to place.

This attachment has all the adjustments necessary to work legs of usual length, and up to 3 inches in diameter.

This machine, with its attachment, is made by W. F. and John Barnes, Rockford, 111. |

|

1880 W. F. & John Barnes Co., Foot-Powered Former

1880 W. F. & John Barnes Co., Foot-Powered Former

1880 W. F. & John Barnes Co., Foot-Powered Former

1880 W. F. & John Barnes Co., Foot-Powered Former

1880 W. F. & John Barnes Co., Foot-Powered Former Knives

1880 W. F. & John Barnes Co., Foot-Powered Former Knives

|

|