Located at 384 Atlantic Avenue, Boston, MA, Edwin E. Bartlett was the successor to C. F. Harlow & Co. (ca 1899). He had worked for Harlow since 1866. Shortly after taking over the business, Bartlett introduced the "Federal" bench planer which was quite successful and surviving examples can still be found.

In 1916 Bartlett moved to Nashua, NH, and sometime after that the business was reorganized as Greenerd Press & Machine Co.

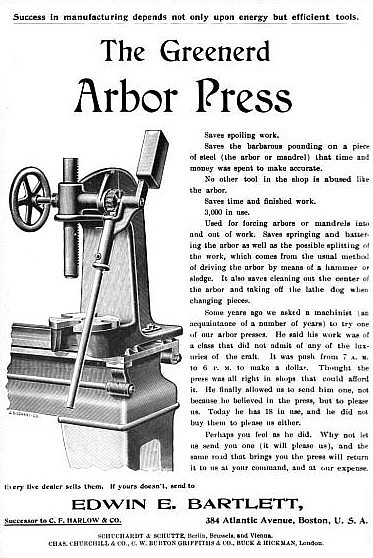

From January 1900 Science & Industry

Information Sources

- An 1870 sewing-machine patent (no. 107,041 and RE8,283) was granted to Charles F. Harlow of Boston and assigned (by mesne assignments) to William L. Grout of East Stoughton, Mass.

- 1873 The Boston Directory lists William C. Harlow of C. F. Harlow & Co., 19 Harvard Place. James W. Guerusey was also employed at C. F. Harlow, 19 Harvard Place.

- An 1874 patent (no. 154,603) for a sheep-shearing machine was granted to Lavinas B. Hamilton and Charles F. Harlow, and assigned to Philander Harlow of Hyde Park.

- 1875 The Boston Directory lists Charles F. Harlow and Philander Harlow of the Harlow Bros. Harlow Bros., of 19 Harvard pl., made "horse clipping and sheep-shearing machines".

- An 1877 sewing-machine patent (no. 192,568) was granted to Edward Corbett and Charles F. Harlow and assigned to Corbett. An 1877 tobacco-cutter patent (no. 192,579) was granted to Charles F. Harlow and assigned to John Kimball of Boston.

- The 1885 Boston City Directory has no entry for Edwin E. Bartlett or Charles F. Harlow.

- 1889 Boston City Directory, page 112, lists "Bartlett Edwin E. (Charles F. Harlow & Co.) 384 Atlantic av. h. at Hyde Park". On page 581, "Harlow Charles F. & Co. (E. E. Bartlett), special machinery, 384 Atlantic av. h. 24 Ruggles".

- The 1890 Congressional Record lists "Charles F. Harlow & Co., machine-shop, Boston, Mass." as signing a petition related to duties on pig-iron and scrap-iron.

- A 1900 patent (no. 648,54) for a resilient wheel for bicycles or automobiles was granted on one Charles J. Groves and partly assigned to Charles F. Harlow and William P. Stratton, all of Boston.

- Science and Industry Jan 1900 page 560

- American Foot Power and Hand Power Machinery by Kenneth L. Cope, 2001 page 30

- The following history is quoted directly from the Greenerd website. The early history given within should not be relied upon.

Greenerd’s history dates back to before 1883. A man by the name of Robert Greenerd developed and patented the arbor press in 1860. This was the company's original product He thought of this as a device to press arbors into lathe, thereby eliminating a primitive sledge-hammer method.

In 1884, Edwin E. Bartlett purchased Greenerd's patents and started manufacture in a Boston loft. Working with the Massachusetts Institute of Technology, Bartlett developed the arbor press from a simple small machine through a complex of special types designed to press up to 30 tons utilizing compound gear’s and leverages. Improvements followed and Greenerd developed a reputation for quality and craftsmanship.

The need for more space led Mr. Bartlett to relocate, first in South Boston, then later in Nashua, New Hampshire, where Mr. Bartlett operated the company successfully until his death in 1930. Mr. Warren L. Martin, his son-in-law, then took over and in 1937 incorporated as the Greenerd Arbor Press Co., Inc.

In 1934 the first Greenerd hydraulic press design was built. This was the first of many and the beginning of a new era for Greenerd. Continuing to build value and integrity into its product, the company grew steadily in the hydraulic press field becoming known for reliable and practical designs. When Mr. Martin retired in 1962, he sold the Greenerd Arbor Press Co., Inc., to Calculagraph Co. of East Hanover, New Jersey.

The new owners continued the successful policies, allowing no compromise with quality and, renamed the company: GREENERD PRESS & MACHINE COMPANY, INC. - in keeping with its larger role in industry.

Since 1962 a steadily increasing number of Greenerd presses of all types have been delivered. With confidence in their ability to design and produce the best, the Greenerd directors, headed by Mr. William C. Moodie, Sr., have encouraged the expansion of the hydraulic press line while continuing the old reliable arbor presses.

Greenerd's present broad press line includes hand operated arbor presses, open-gap (C-Frame) hydraulics, 4-post hydraulics, custom-built presses, hydraulic expanding machines, and air-operated 30-100 ton economy presses, including a hand-pumped compact 30-ton laboratory press. Overall, Greenerd press tonnages range from 1/4 ton to 500 tons of force.

Further factory enlargement was necessary in 1967 to handle the increased hydraulic press business. Bigger presses and more of them are now built in a new wing equipped with the latest facilities for handling and assembling large machines In a time of rapid technological changes Greenerd s practical press designs lead the industry, but Greenerd's philosophy remains unchanged:

GREENERD BUILT" means built for performance and built to last.