Image

|

Title: |

1869 Article-Aveling & Porter, Steam Traction Engine |

|

Source: |

Recent Improvements in the Steam Engine, 1869, pg. 265 |

|

Insert Date: |

2/5/2015 10:00:17 PM |

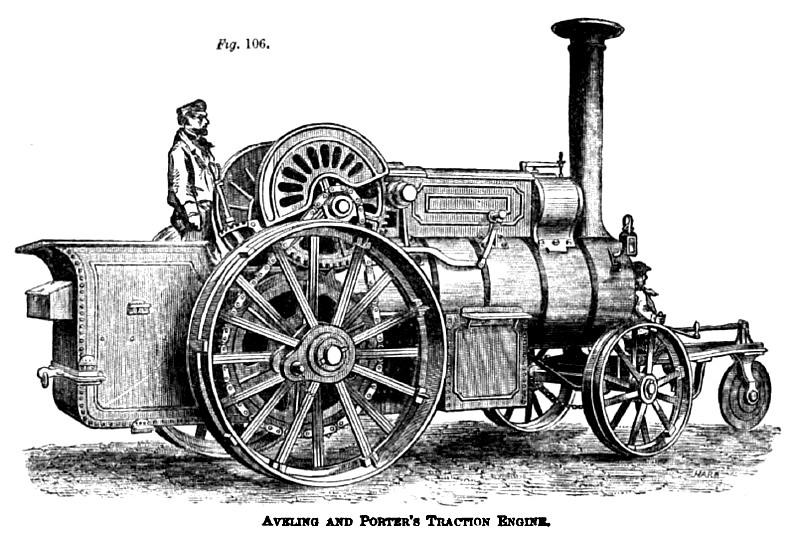

In Aveling's Patent Traction Engine, fig. 106, manufactured by Messrs. Aveling and Porter of Rochester, there is a single cylinder surrounded by a steam jacket, which is in direct communication with the boiler by means of steam ways or orifices made in the top of the boiler. There will be little tendency to prime in this engine, as the cylinder is brought to the forward part of the engine, and on ascending inclines the cylinder is necessarily fed with dry steam; while, in descending, little steam is required. By this arrangement the use of steam pipes either inside or outside the boiler is dispensed with. Engines with single cylinders and reversing gear, connected to the driving axle by chain gear, have proved themselves to be perfectly efficient They are less complicated, and on the whole are better adapted for general traction purposes than engines with double cylinders.

The working parts are housed in from the influence of the weather. The toothed gearing is also covered with light iron splashers. The propelling gear consists of a pinion at each end of the crank shaft (either of which can be thrown in and out of gear with the spur wheel below by sliding it along a feather on the crank shaft), working into spur wheels on a counter shaft below. On this shaft is a chain pinion with chilled teeth, to take in a pitch chain made of wrought-iron links with steel pins. In the brackets carrying the shaft there are curved slots, struck from the centre of crankshaft above, for taking up the slack of the endless driving chain. These pinions are kept in the positions required by means of a simple clip of spring steel embracing the shaft, and lined with leather. The adjustment for taking up the slackness of the chain is effected by the brass bearings carrying the shaft being kept up in the slot by a block at the bottom of each. There is another cast-iron block above, lying on the bearing, and kept down by a set screw. When the chain has to be shortened, the thinner block below is taken out, and the thicker one above is substituted in its stead. The brass step is thus fixed in a perfectly firm and solid adjustable bearing. The gearing is connected to the driving wheels by means of the endless chain passing round the chain pinion on the counter shaft, and a large chain wheel keyed on the axle. The driving wheels are 6 ft. 6 in. diameter; on the face of the wheels is an outer tire, parts of which may be removed and replaced by angle iron paddles or clips for use in passing over soft and yielding ground.

The boiler is carried through from end to end without any break in the configuration, whereby the use of angle iron is dispensed with. The stay bolts of the fire-box are pitched 4½ in. from centre to centre. The fire-box is adapted for burning wood or coal fuel. The water for feeding the boiler is carried in a tank made of wrought-iron plates and bolted to the side plates of the fire-box, which are carried out for this purpose. The draw bar is formed of T iron, the ends of which are returned, or bent back, and bolted to the wrought-iron side plates of the tank.

The steerage is effected by a single disc wheel carried on the lower end of a vertical spindle, supported on a collar-bearing on the front end of a pair of angle iron shafts secured to the fore carriage of the engine. The upper end of the vertical spindle is provided with a lever-handle extending back towards the steersman, who is seated between the shafts at the front end of the engine. This engine is capable of ascending inclines of 1 in 12, with a load of 20 tons, and with 8 tons will ascend an incline of 1 in 6. On a level road in fair condition it will haul 40 tons with ease.

One hundred and eighty of these engines are now in use in different parts of the world, and are used in sugar and coffee plantations, and in copper and lead mines, in dockyards, and wherever large quantities of materials and heavy weights have to be removed. Messrs. Aveling and Porter have manufactured and exported these engines to Russia for the government, to Jamaica, Queensland, Java, Egypt, Prussia, Buenos Ayres, &c.,; and the increased demand proves that steam power on common roads, and in new colonies, is now attracting the attention which its importance and utility justify. For feeding the traffic of railways steam traction on common roads is particularly valuable. In India, branch railways have been projected for this purpose, which were at one time intended to have a narrower gauge than the ordinary railways of that country. But the injudicious break of gauge has now been abandoned, and all railways, whether trunk or branch, established to carry on the communication of the country, are intended to have the same gauge. Prior to the formation of a railway, however, it is advisable to make a metalled common road on which traction engines may run; and when the traffic has thus been by degrees nursed up to a certain point of magnitude, it will become advantageous to lay down rails for the engines to run upon. This is the proper course of development in a new or undeveloped country; and the construction of expensive lines of railway in districts covered with jungle, and destitute of population, cannot be justified by any principle of reason or any indication of common sense. |

|

1869 Aveling & Porter, Steam Traction Engine

1869 Aveling & Porter, Steam Traction Engine

|

|

|

|