|

Title: |

1904 Article-H. W. Ward & Co., Turret Lathe |

|

Source: |

Page's Magazine Jul 1904 pg. 60 |

|

Insert Date: |

1/6/2013 7:56:00 PM |

A new 2-in. Centre Friction Geared Checking Lathe with 4 3/8-in. hole in Spindle.

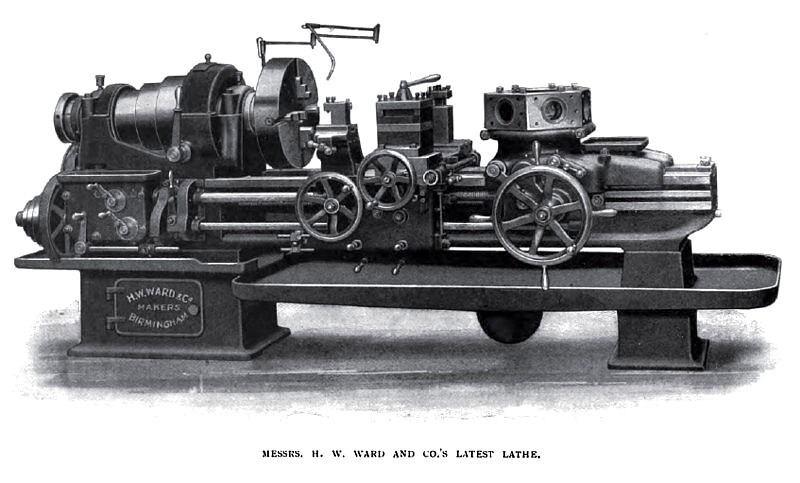

We are indebted to Messrs. H. W. Ward and Co. for the accompanying illustration of a new lathe, which is a heavy tool suitable for all classes of chucking and bar work.

The bed is strong, wide and well ribbed; it has large bearing surfaces, square edges, and is supported on two box pedestals, and has a large oil pan so arranged as to collect the oil and strain it into a well underneath, go which the pump is connected.

The headstock carries a spindle of hard steel, which runs in split parallel gun-metal bearings, arranged with caps to take up the wear and friction washers to take the thrust; the hole through the spindle is 4 3/8-in. wide to allow of 4¼-in. black bars being passed through. The driving cone has three speeds, and carries a belt 4½-in. wide. and the gear is of the power of 8 to 1, and being a friction drive may be thrown in or out whilst the machine is in motion by the lever in the front of the headstock.

The cross-slide has automatic sliding and surfacing feeds, and is also arranged for screw-cutting: the top slide carries on the front a square turret for four tools, and has an indexing arrangement for bringing the tools into position; on the back of the slide is an ordinary square tool-post to carry two tools. The feed motion to cross-slide and saddle is taken from the tail end of the spindle by a train of spur gear to the change boxes under the headstock. These boxes contain eight changes and a reversing motion any of which may be instantly obtained whilst the machine is running by the use of the three levers on the front of the box. Four of these changes of motion communicate with leader hub, so that four different threads may be cut from the one hub, either right or left hand.

The turret is hexagonal in form, and is 15¼-in. across the flats; it is carried on a strong saddle which slides on the bed and may be operated by either hand or feed. The turret revolves on a large bung and is indexed by a cylindrical bolt of large diameter, which is hardened and ground, and fits in locating bushes, which are also hardened and ground.

The bolt is withdrawn by lever when it is required to revolve the turret, and is returned to its place after revolving by a spring sufficiently strong to properly locate the turret, which is then firmly locked in position by a grip ring around the outside diameter of the turret.

The feed to the turret is driven by the three-speed cone at the tail end of the lathe, and two extra changes by gear are provided by moving the lever at the right hand of the change box; thus six feeds in all are available, for the turret and the gear is so arranged that the change is such as will he useful when boring and reamering.

The feed may he put in action from the front of the turret. Six stops are provided, one for each tool being used, and these are arranged in conjunction with a self-selecting arrangement under the turret, which ensures the correct stop being always in position, whether the turret is revolving backward or forward. There is a complete arrangement of oil pump and fittings. The countershaft has two pairs of fast and loose pulleys, 16-in. and 20-in. diameter, which, together with the cone pulley and gearing, gives twelve changes of feed to the spindle. The lathe will swing over bed 22½-in. and over saddle 14-in. diameter. It takes between face of turret and chuck 4 ft. 6in., and weighs approximately 4 tons. |

|

1904 H. W. Ward & Co., Turret Lathe

1904 H. W. Ward & Co., Turret Lathe

|

|