|

Title: |

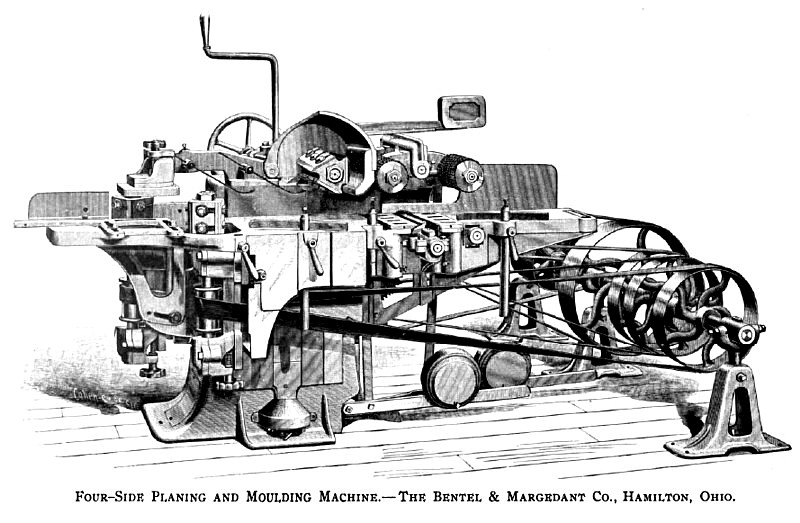

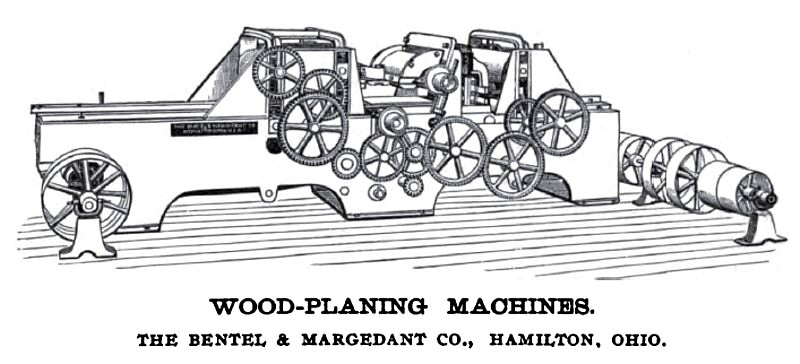

1895 Article-Bentel & Margedant Co., 4-Side Planing & Moulding Machine |

|

Source: |

Industry Magazine, Nov 1895, pgs. 656 & 657 |

|

Insert Date: |

12/13/2012 8:25:08 PM |

It will be remembered that "industry" began about seven years ago a "crusade" against the method in which planing and moulding machines were arranged in this country. The subject was taken up from time to time, showing the faults and inconsistency of reversing the hand method of planing when the same work is done by machines, also showing that in no other country in the world was planing done in the same manner, that is, to thickness and form a face at the same time on "top" of the timber, and then gauge profile work, tonguing, grooving, or other operations from the "back" and finally when all other operations were done plane the bottom, which is the true face, that should be planed first.

The objections are that the timber slides on the rough side, and unless flexible enough to bend, the line of the top or profile is a reproduction of the bottom or rough side, and if a piece is too thin, the un-planed side, as in flooring or ceiling, comes on the upper or face side, and the piece is lost, also if the thickness varies by the top knives wearing or by adjustment the "match" is destroyed, because the side work is gauged fiom the bottom of flooring or the inside of ceiling.

There are other faults or imperfections in the system that have prevented the sale of American machines in other countries where there has been a large foreign trade in wood-working machines of other kinds. To ascertain how far this matter had engaged attention we applied to one of the most able and progressive firms in this country', the Bentel & Margedant Company, at Hamilton, Ohio, and are astonished to find that all their machines for planing more than one side at a time are arranged to plane a face on the bottom first, and then follow with the other sides.

We have not space this month to give illustrations of their practice beyond a moulding machine, shown on the page opposite, and a

diagram at the head of this article illustrating the arrangement of their planing and matching machines, in both of which, as may be seen, the bottom cutters are in advance. The following extract from one of the company's circulars gives their view of the matter:

'' A chief advantage, and one of great importance, is placing the fourth or lower cutterhead at the front of the bed instead of in the rear, which is still the faulty primitive construction pursued by other makers.

"The old established rule of planing the lower side of material first, in hand planing, to insure a smooth surface, from which base the size and shape and depth of cut can be laid off accurately, holds good as well in a machine planing on two or more sides as done on a moulding machine.

"It is also of importance to plane that surface on which the material slides on the accurately planed table, free from any grit or loose splinters, as thus a solid firm bearing free from rocking motion is secured, and the friction resulting from the pressure of the necessary pressure plates and hold-down springs is reduced to a minimum.

"The material is received by the first feed roll, and passed over the lower head, affording the smooth and accurate lower surface before the other three cutter-heads are reached. The advantages of thus establishing a free and easy forward movement of the material on its now smooth sliding surface, and of an accurate base line from which measurements can be taken, not changed by the subsequent planing of other heads, will be appreciated."

We may also mention other improvements and designs, such as are suggested by this intelligent view of planing, some of which will be illustrated in future numbers of " Industry." |

|

1895 Bentel &, Margedant Co., 4-Side Planing & Moulding Machine

1895 Bentel &, Margedant Co., 4-Side Planing & Moulding Machine

1895 -Bentel & Margedant Co., Wood Planing Machine

1895 -Bentel & Margedant Co., Wood Planing Machine

|

|