|

Title: |

1895 Article-Ober Manufacturing Co., Lathe for Irregular Forms |

|

Source: |

Industry Magazine, Jun 1895, pg. 352 |

|

Insert Date: |

12/13/2012 10:46:09 AM |

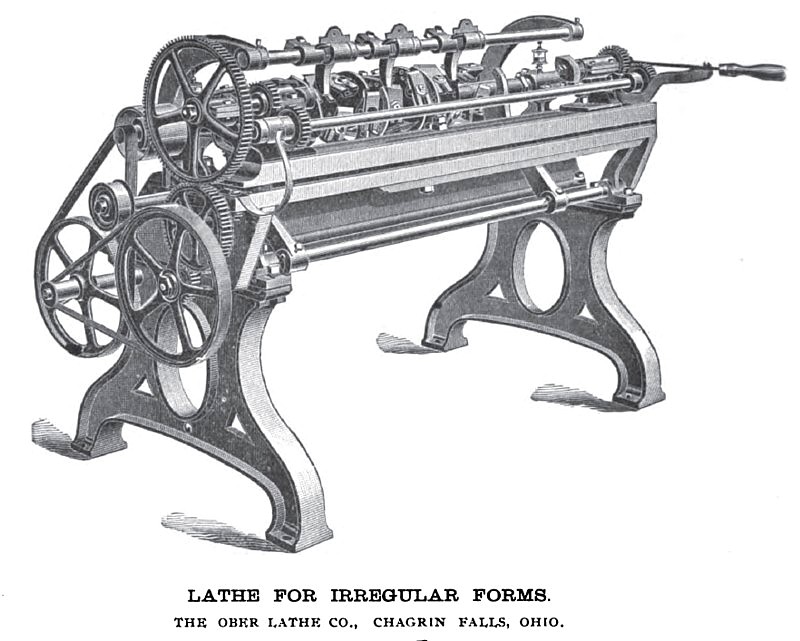

The engraving shows in perspective a machine for turning or shaping irregular work, which seems quite a departure from common practice in this country.

These lathes are employed in making tool handles, such as those for axes, hammers, and picks; also wheel spokes, whiffle-trees, and the like. They will produce round, oval, polygonal, or square sections, and it is said will produce from 200 to 500 short pieces or 200 to 250 wheel spokes in an hour, ready for the sand belts that follow.

These machines belong in the class called "copying," producing duplicates from a model, not necessarily the same in size, but having like relations in respect to diameters in the cross section each way. They present some curious problems in working and are a product of experiment rather than of calculation.

There are two peculiar features: the elastic element that enters into the vibration to produce oval or other irregular cross sections, and the inertia of the piece being cut, or of the piece and its supports. The first is required to produce the rhythmic vibrations without jar, and corresponds to crank motion, so the vibrations can take place with great rapidity. No one would suppose, inferentially, that a piece of oval section, for example, would “ follow “ a pattern at fifty to a hundred revolutions per minute, 'but this is what takes place. Again, if we imagine a thin piece, like an axe handle or a long carriage spoke being struck by the cutters, it will seem that its rigidity would not oppose such a force. This is provided for by making the cutter heads of large diameter, and giving them a very high velocity at the periphery, so the "time" of contact, measured on the arc, is infinitesimal, and the inertia of the wood, with what are called " back-stays ” of some weight, immediately opposite the cut, prevents yielding of the wood and produces tolerably smooth surfaces. The machines, of which a middle size is shown in the engraving, seem to involve a good deal less detail than the old type, and are certainly more accessible and simple in construction. The company confine themselves to irregular turning machinery and the finishing apparatus required therewith, consisting of sanding, polishing, and “waxing” the work. |

|

1895 Ober Manufacturing Co., Lathe for Irregular Forms

1895 Ober Manufacturing Co., Lathe for Irregular Forms

|

|