|

Title: |

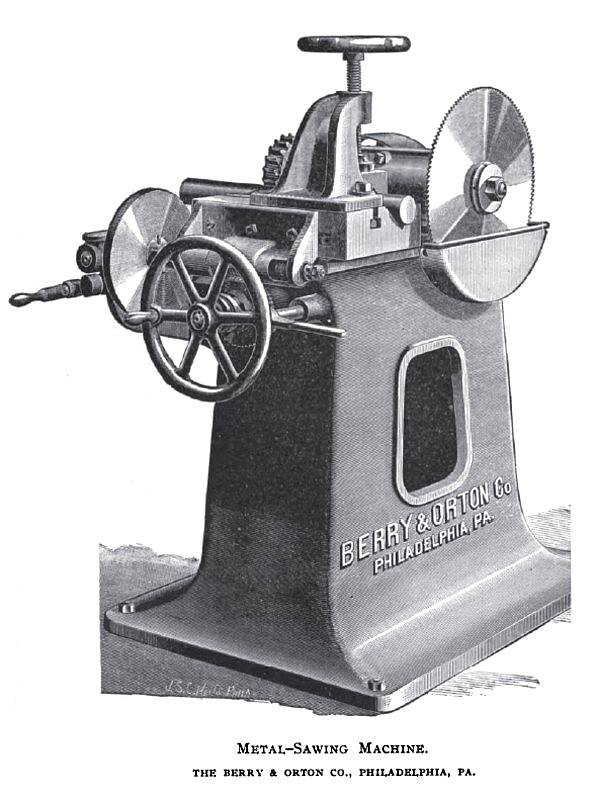

1894 Article-Berry & Orton Co., Metal-Sawing Machine |

|

Source: |

Industry Magazine, Feb 1894, pg. 96 |

|

Insert Date: |

12/6/2012 1:14:25 PM |

The development of cold sawing iron and steel has taken place, in so far as any wide use, during a dozen years past, and should go far toward convincing us how little after all we know of manipulative processes, and how they are left to be discovered by accident.

It will be safe to conjecture that for a century at least, the fact of a wood saw being destroyed if it came in contact with iron, deterred people from applying such saws to cutting iron, although the hacksaw was all the time proof of how rapidly iron could be cut with a proper saw at a slow speed. It is merely a milling or planing operation, obviously possible and practicable if reasoned about, but it was left for tentative development.

One of the first uses in this country was in cutting off "stock" for machine drills, the hardest kind of cast steel bars, and one of the most difficult things to saw. In the old world it also came in a "left-handed" way, because the use of circular saws, now principally employed, followed the use of baud saws, but when circular sawing once started, about ten years ago, it spread within three years or so far and wide. American machine-tool makers were late in taking it up, but have made up since by some very ingenious designs, among which is the one illustrated on the page opposite, and to which attention is now called.

The machine is to cut off square or round bars to five inches diameter, and is, in a good many respects, an unusual adaptation of machine motions and functions with the fewest possible parts. The positions and movements seem to fall into place naturally and completely.

The saw is driven by a tangent wheel, seen over the top, meshing into a strong worm shaft at the side of the machine. The saw spindle is on a movable carriage, and the tangent gearing provides for the traversing of the carriage and saw.

On the worm shaft is a movable friction pinion that drives the disc wheel on the left, at varying speed as the pinion is adjusted by the handle on the extreme left. The large hand wheel in front is on the end of a central feed screw that moves the saw carriage. This feed screw is driven by the tangent gearing in front when the machinery is operating, or is disengaged by a clutch and the hand lever on the right, so the saw can be moved forward or back quickly by the large hand wheel.

The planes of the several shafts permit the employment of three sets of tangent gearing, and the reduction for feed, which is very slow, is placed at control by this gearing, and is varied, not by steps, but in regular progression each way, as the work demands.

We have here a traversing carriage and saw spindle, variable power feed and hand movement of the carriage, with but a single member provided for transmission alone, that is, the small cross shaft in front of the machine. All moving parts are covered from dirt and chips; there are no feed bolts, cones, or other contrivances, and we venture the opinion that the design of this machine has not been excelled in this country or elsewhere for one of its class and purpose. There are three sizes made, of the same general design. |

|

1894 Berry & Orton Co., Metal-Sawing Machine

1894 Berry & Orton Co., Metal-Sawing Machine

|

|