|

Title: |

1895 Article-Defiance Machine Works, Keyseat Cutting & Slotting Machine |

|

Source: |

Chicago Journal of Commerce, 27 Jun 1895, pg. 11 |

|

Insert Date: |

11/6/2012 9:34:52 PM |

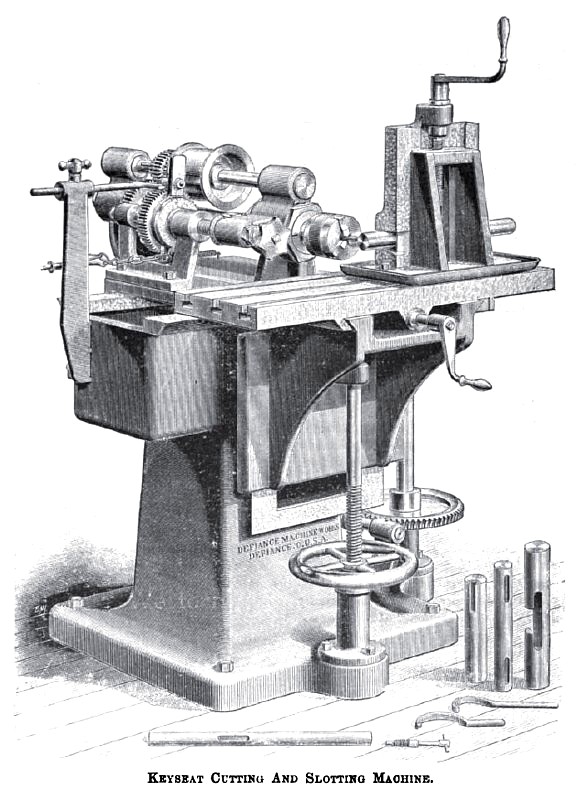

KEYSEAT CUTTING AND SLOTTING MACHINE.

We present herewith an engraving of s machine designed for uniting keyseats and splines in shafts, or for slotting holes through boring bars, tool-posts, etc. The work is held, usually in the vise shown, which is bolted to s platen 30 inches long, haying planed T-slots, a 6 inch movement in line with the spindle and 10-inch vertical adjustment.

The cutters are made of drill rod, and are preferably held in a three-jawed chuck as shown, though if preferred the spindle in provided with a Morse standard taper hole. The saddle, carrying the spindle, is automatically fed along the bed and reversed at each end of the out, the cutter at the end of each movement being also automatically advanced the required amount for the next cut. This movement is effected by the feed screw and mechanism seen at the left of the cutter spindle. The cutter has a movement along the bed of 10 inches and will cut 2½ inches deep. Micrometer adjustments are provided for length and depth of cut, and when set and started, the movements are entirely automatic.

The cutter spindle is of steel 1 15/16 inches diameter and runs in taper bronze bearings with means for taking up wear without disturbing alignment. Pains have been taken to make the machine heavy enough to prevent vibration when doing the heaviest work; its total weight being 1,200 pounds.

It is made by the Defiance Machine Works, Defiance, O. |

|

1895 Defiance Machine Works, Keyseat Cutting & Slotting Machine

1895 Defiance Machine Works, Keyseat Cutting & Slotting Machine

|

|