|

Title: |

1895 Article-Rivett Lathe Mfg. Co., Rivett Automatic Grinder |

|

Source: |

Chicago Journal of Commerce, 21 Feb 1895, pg. 18 |

|

Insert Date: |

11/6/2012 7:05:26 PM |

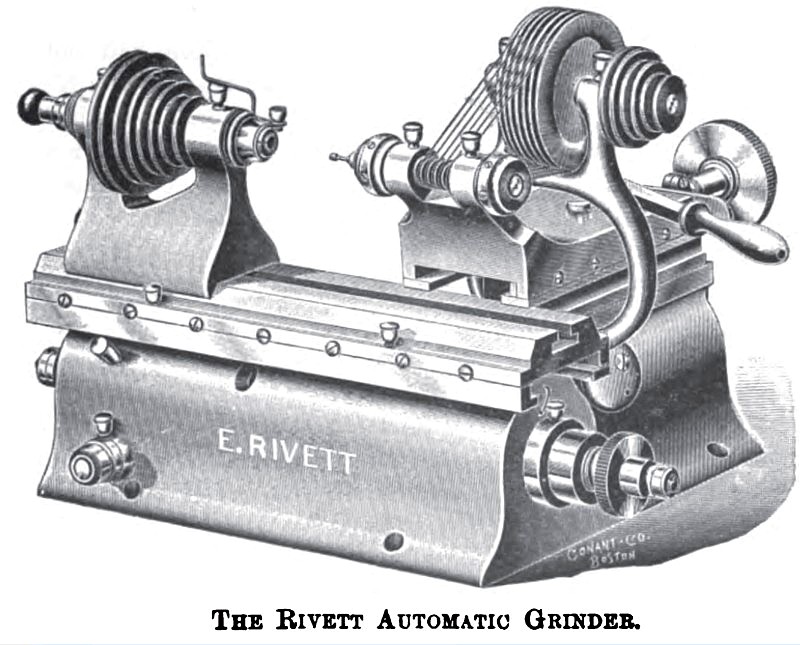

THE RIVETT AUTOMATIC GRINDER

We present herewith an engraving of a grinding machine, which was designed especially for grinding the hole in the hardened draw chucks used in the "Rivett" lathe.

As the holes in these chucks include sizes as small as .013 inch, and the lap with which they are ground must be somewhat smaller, it is readily seen that the attainment of the speed required for efficient grinding u one of the chief problems; and the quarter inch spindle in this machine regularly runs at 60,000 to 75,000 revolutions per minute, and has attained 100,000 revolutions. At this speed it is found that the spindle is much more rigid than at the lower speeds usually employed.

It will be noticed that six small round belts are employed to drive the spindle, and that the larger pulley is so mounted as to be readily moved towards or from the spindle to adjust the belt tension.

The other features of the machine will be readily understood. It will be noticed that the platen is fitted to receive the regular lathe head, and this platen is moved automatically upon its slide during the grinding. Four of these machines are in use in the shops of the Faneuil Watch Tool Co., Boston, where they were built—three of them for grinding chucks and the fourth for grinding the taper hole in tail stock spindles, and it is of course evident that they are adapted for any small, light and fine grinding. |

|

1895 Rivett Lathe Mfg. Co., Rivett Automatic Grinder

1895 Rivett Lathe Mfg. Co., Rivett Automatic Grinder

|

|