|

Title: |

1906 Article-George Swift, Three Spindle Drilling Machine |

|

Source: |

Page's Engineering Weekly, 16 Feb 1906, pg 361 |

|

Insert Date: |

6/7/2012 12:37:32 PM |

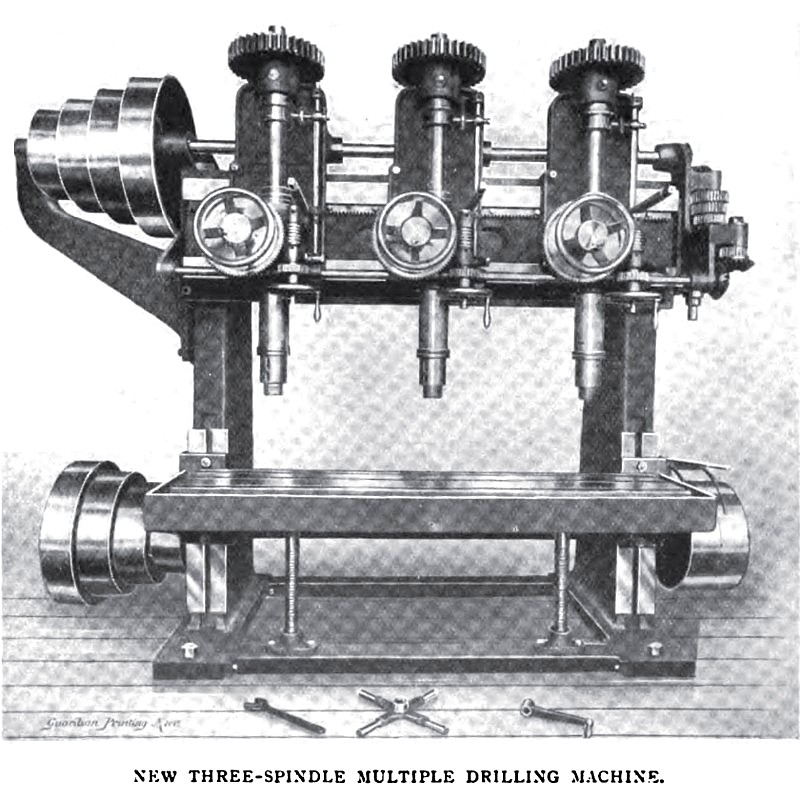

Three Spindle Multiple Drill By George Swift, Halifax

The multiple drilling machine shown in the accompanying illustration, is designed to bore three 3½-in. holes in mild steel at once. The spindles, 3½ in. in diameter with 15-in. feed, can be fed down by hand or power, and have quick release. They are balanced by means of springs and are independent, so that, if required, three different jobs can be done at the same time. The spindles have ball thrust at top and bottom, and work in long steel sleeves on which the feed racks are cut.

Practically the whole of the gears are of steel, and the machine is entirely self-contained, being driven by fast and loose pulley, 24 in. diameter for a 6-in. belt, the cone being 30½ in., 25½ in., 21 3/8 in., and 17 in. diameter

respectively for 6-in. belt. The table rises and lowers by worm, worm-wheel, and screw; the working surface being 7 ft. by 1 ft. 4 in., with T slots cut out of the solid and an oil channel for the lubricant, The saddles are each adjustable along the cross slide by rack and pinion.

The distance between the inside faces of the cross-slides is 6 ft. 3 in., and the machine will admit from the top of the table to the under side of the spindle, maximum 38½ in., minimum 20 in. The maximum distance between the centre of the two outside spindles is 67 in. minimum centres spindle to spindle 17½ in. Four rates of feed by gears are provided. The net weight of the machine is six tons. |

|

1906 George Swift, Three Spindle Drilling Machine

1906 George Swift, Three Spindle Drilling Machine

|

|