|

Title: |

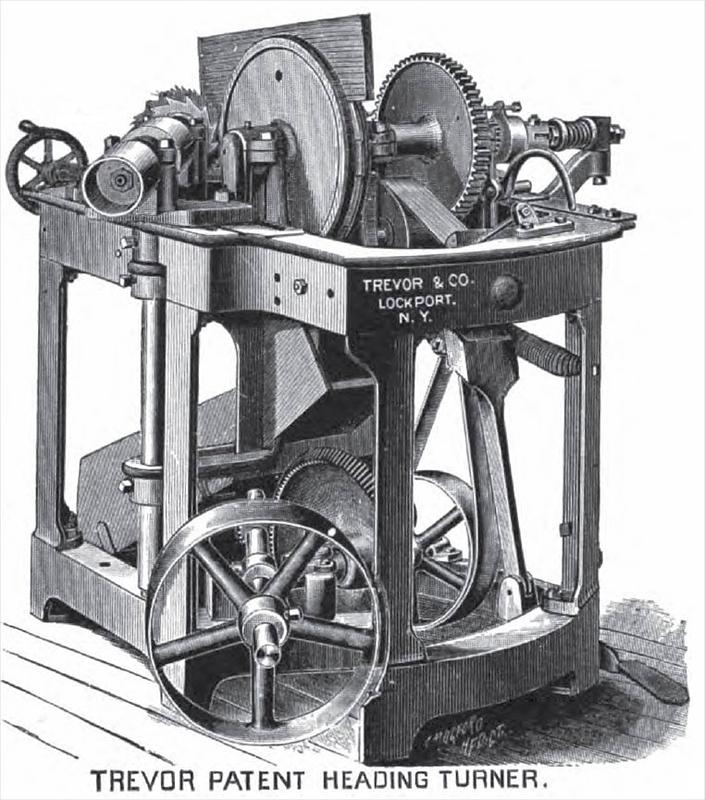

1906 Article-Trevor & Co., Barrel Heading Turner |

|

Source: |

The National Coopers' Journal Jul 1906, pg 13 |

|

Insert Date: |

12/29/2011 7:22:46 PM |

The New "Ontario" Head Turner — To meet the needs of many clients for a turner to circle heads of large diameters, The Trevor Manufacturing Co., Lockport, N. Y., have developed one having a range of from 20 to 40 inches. This is on the same general design of their famous Centennial Heading Turner, which is here illustrated, with only such changes as are required to better fit it for the larger work. Trevor & Co., say they can supply this turner for circling heads with either square or beveled edges. This is a very useful machine for circling heading for crockery casks, tobacco hogsheads, and various round packages having heads of considerable diameters and of a thickness not greater than one inch. "This turner," say the manufacturers, "has an automatic let-off to discharge the heads. A special and important feature in its construction is the casting of the main frame in one piece without joints, which secures a far better frame than if it was built up of separate pieces fastened together with screws. The Centennial Heading Turner clamps the heads before they reach the saw, and is therefore free from the nuisance of throwing heads, so common in many turners heretofore built. The slack work turners have turned over 6,000 flour barrel heads in ten hours, but about 5,000 heads per day is the usual capacity. These turners will circle any size of slack work heading from a 10 inch nail keg head to a 20 inch head, and, if so directed in the order, we will extend the range so as to turn up to 24-inch heads, or we will furnish the new "Ontario" as described above. We furnish with the turner, at list prices, the proper clamps and saws for 17 1/8 flour barrel heading. For larger and smaller we can supply the proper extra clamps and saws which are not included in list price. On special order w e can build them to turn 9-inch heads not over 3/8 inch thick. The countershaft must be placed overhead, above the machine.

"The Centennial Heading Turners arc also adapted to circling uneven tight barrel heading. To do this we build them with slower rate of feed, and we can supply a combined machine to do both tight and slack work.

"For additional particulars as to this machine or our well known makes of stave, veneer or basket machine you have only to address us at Lockport, N. Y." |

|

1906 Trevor & Co., Barrel Heading Turner

1906 Trevor & Co., Barrel Heading Turner

|

|