|

Title: |

1895 Article-Pedrick & Ayer, Link Miller & Slotter |

|

Source: |

Modern Mechanism 1895 pgs 513-514 |

|

Insert Date: |

6/24/2011 12:42:12 PM |

|

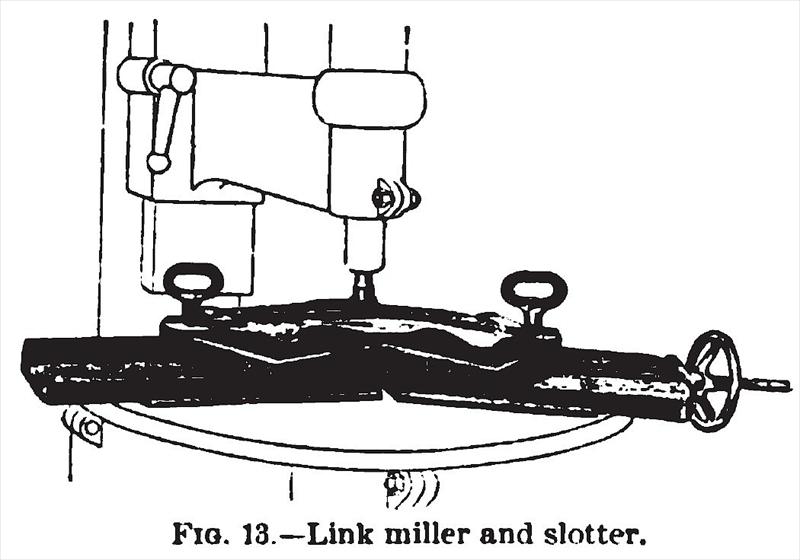

Leeds' Link Miller and Slotter—This machine (Fig. 13), built by Pedrick & Ayer, of Philadelphia, is used as an attachment either to a heavy milling-machine or a strong drill-press. It will mill out links to any desired radius. It is designed on the principle that the apex of any angle will touch or describe all parts of a circle whose versed sine is equal to the perpendicular where the base is formed by the chord of the arc. It consists of a jointed frame having dovetailed slots running lengthwise, to carry a second frame that has the link-blank secured in it. The second frame is actuated by the screw and hand-wheel and describes a circle, according to the angular position of the lower or jointed frame; flanges are cast on the bottom of the frame for the purpose of bolting down on the table or platen. In the center of the lower frame, at the center of the joint, is a bronze bushing that is set exactly under the center of the drill-press spindle; this serves as a lower support for a boring-bar and the shank of the milling-tool arbor. In practice it is found more convenient to drill a hole in one end of the link to be slotted, large enough for a boring-bar to pass through; then, by using a double-end cutter, the slot is cut out to nearly the finished size. The link is then "moved along 3/8 or 1/2 in., and is cut through again until the stock is removed. A milling-cutter similar to a reamer is then used, and the slot is finished to the radius for which the link is set. With this attachment it is claimed that a link 20 in. long can be finished in about 4 hours. |

|

1895 Pedrick & Ayer, Link Miller & Slotter

1895 Pedrick & Ayer, Link Miller & Slotter

|

|