|

Title: |

1895 Article-Rochester Machine Tool Works Ltd., Acme Automatic Steam Engine |

|

Source: |

Modern Mechanism 1895 pg 320 |

|

Insert Date: |

6/11/2011 9:37:11 PM |

|

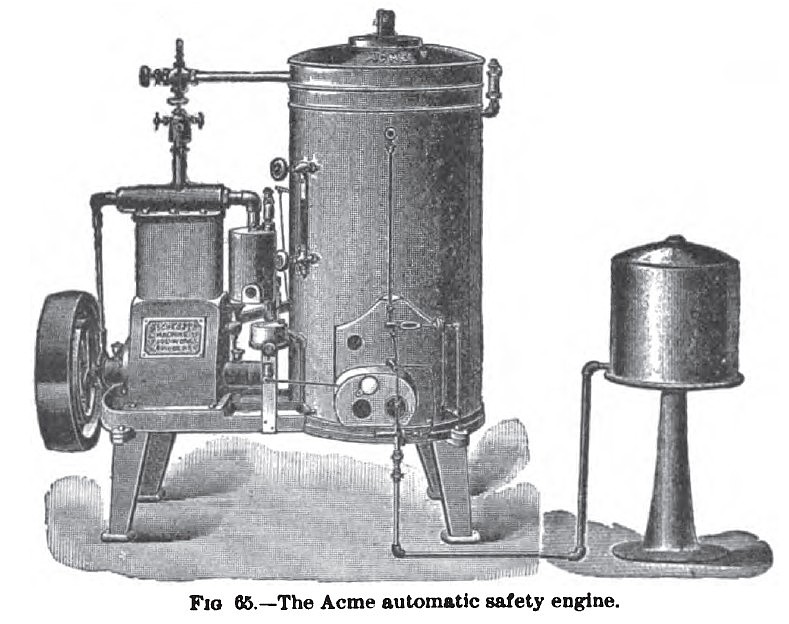

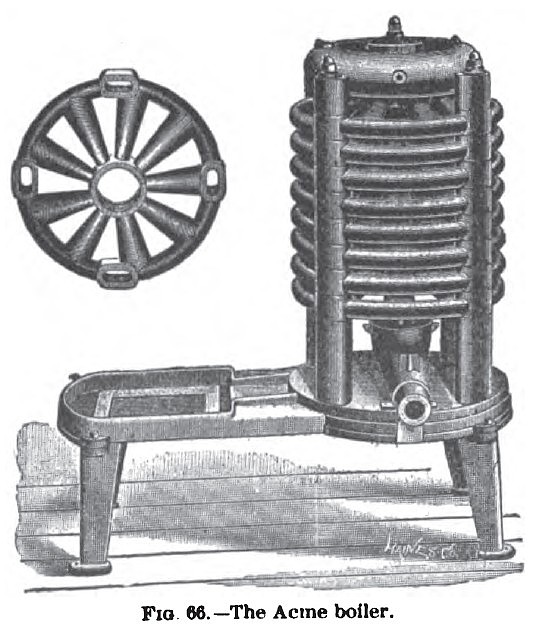

The Acme Automatic Safety Engine and Boiler, made by the Rochester Machine-Tool Works, Rochester, N. Y., is shown in Figs. 65 and 60. The engine (Fig. 65) is an upright double-cylinder, single-acting engine, with cranks 180° to each other. The pistons being 1½ times the stroke in length, form their own guides, the wrist-pins being slightly below the center of the pistons, and the steam-rings above and below the wrist-pins. The valve is of the balanced rocking type, and is placed on the top of the cylinders, the valve-case forming the cylinder-heads. The fly-wheel contains the automatic governor, which regulates the admission of steam to suit the varying loads, by changing the throw of the eccentric that actuates the valve. Lubrication is accomplished by carrying in the crank-case a mixture of oil and water, into which the cranks dip at every revolution. The boiler is shown in Fig. 66. It is of the sectional type, the water being carried in a series of rings connected by inclined tubes that break joints. The boiler is double-jacketed to prevent loss of heat by radiation. A large dome on top is used to dry the steam. The water-supply is maintained by a pump worked from the main shaft, which forces the water through a coil-heater, where it is subjected to the effects of the exhaust steam before entering the water-leg of the boiler. The supply of water to the feed-pump is regulated by a ball-float in a case attached to the boiler, which, by means of levers, controls the amount delivered at each revolution of the engine, and may be adjusted to maintain the desired level of water in the boiler under the varying loads to which the engine may be subjected. The fuel is kerosene-oil of 110° to 115° fire-test (this grade giving the best results), atomized by a steam-jet, and controlled by an automatic fire-regulator, that reduces or cuts off entirely the supply of fuel when the steam-pressure reaches the limit at which the regulator is adjusted. Tins fire is easily controlled, and gives an even and constant supply of steam. The tank containing the oil is placed on a suitable stand, the bottom being as high as or higher than the burner. The oil flows to the atomizer, and is regulated by the cap of the atomizer, as before stated. There is also an automatic self-closing valve located on the oil-pipe, that shuts off the oil when steam is shut off from the atomizer, either by hand or the action of the fire-regulator. |

|

1895 Rochester Machine Tool Works Ltd., Acme Automatic Steam Engine

1895 Rochester Machine Tool Works Ltd., Acme Automatic Steam Engine

1895 Rochester Machine Tool Works Ltd., Acme Boiler

1895 Rochester Machine Tool Works Ltd., Acme Boiler

|

|