|

Title: |

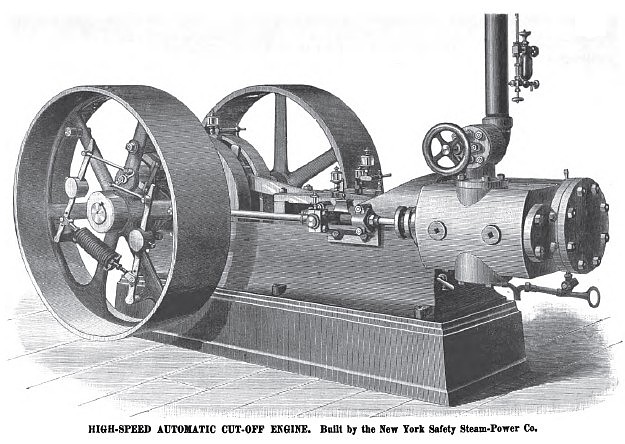

1890 Article-New York Safety Steam Power Co., Automatic Cut-Off Steam Engine |

|

Source: |

The Steam User 1890 pg li |

|

Insert Date: |

11/11/2012 5:25:31 PM |

The frame of this engine is cast in one piece, and is very stiff and strong throughout—capable of easily resisting whatever stresses may be put upon it. The cylinder is bolted on at one end, while at the other the two main journals for the crank-shaft are located. The bottom of the bed is planed to a true surface, and the foundation bolt holes are accurately located, so that an engine may go upon foundations laid in accordance with drawings, without the necessity of a templet.

Free access is given to the stuffing-boxes, guides, cross-head, etc., and provision made for adjusting the various parts. The crank-shaft is made of forged steel in one continuous piece. The counterbalancing discs are clamped to the cranks and serve to neutralize the weight of the reciprocating parts of the engine. Crank-shaft bearings are large and long, calculated for enduring the severe strains of heavy work. The bearings, or boxes, consist of cast-iron shells, babbitted flush to the edges in such a manner that the shaft and shells cannot come in contact. They are accurately bored and scraped to fit the shafts, and are adjustable in all proper directions, being made in quarter-sections. The bearings, or boxes, of the crank-pin and cross-head pin are of iron, lined with best quality babbitt-metal. All bearings are extra large, more than ample for the maximum rated power of the engine. The piston is fitted with the Dunbar packing. The piston-rod, valve-rod, eccentric-rod and all pins are of the best quality of steel. The connecting-rod is of forged wrought-iron.

The automatic lubrication of the crank-pin, cross-head pin, eccentric strap, valve-rod cross-head, and the crank-shaft bearings while the engine is at high speed, is accomplished by a very efficient system of stationary adjustable sight-feed glass oil-cups and traveling wipers. The internal lubrication of the engine is provided for by the application of a first-class Automatic Cylinder Lubricator. Each engine is fitted with a finished throttle-valve, a set of drip-cocks to cylinder and steam chest, and a set of wrenches. Unless otherwise agreed, each engine is fitted with two wheels of equal diameter and face, both accurately balanced and turned for service as band wheels; one contains the governing mechanism and the other is a plain wheel.

The close regulation in this engine is accomplished by a governor of novel design, so constructed that it is attached in one piece to the wheel; should any part become broken by accident a new part could be attached in a few minutes by any engineer. One size governor will fit any size engine. All the parts of this engine are interchangeable, and are constantly kept in stock by the manufacturers. |

|

1890 New York Safety Steam Power Co., Automatic Cut-Off Steam Engine

1890 New York Safety Steam Power Co., Automatic Cut-Off Steam Engine

|

|