|

Title: |

1890 Article-Webster, Camp & Lane Machine Co., High Speed Steam Engine |

|

Source: |

The Steam User 1890 pg xlviii & xlix |

|

Insert Date: |

4/7/2011 2:01:04 PM |

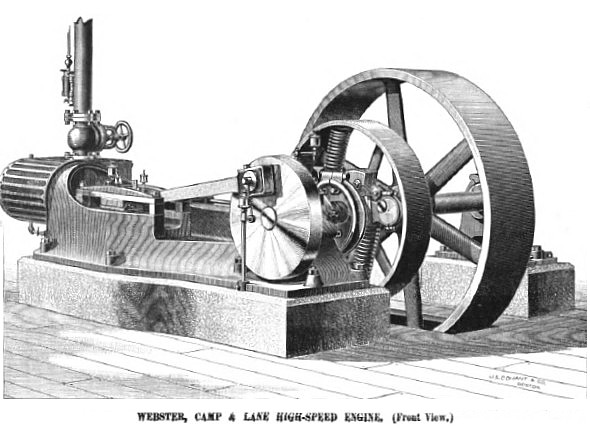

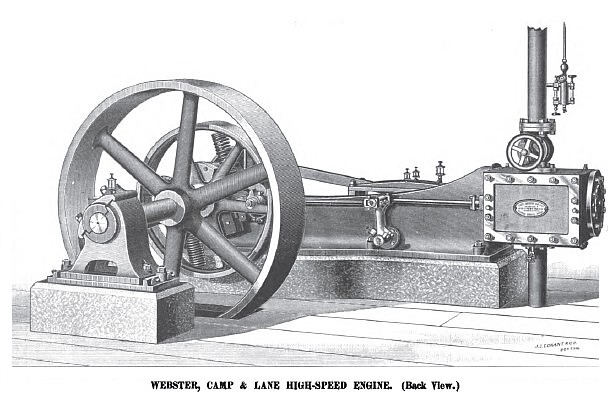

The engravings on the opposite and page following illustrate an engine recently placed upon the market and designed especially for manufacturing, or electrical work as applied to lighting and street railways. The cuts show a design in which the builders use a single valve to govern the steam distribution. They also make an engine in which are used two valves, one governing the admission, release, and compression, the other the cut-off. In both cases the valves are balanced. The single-valve design is particularly adapted to the higher piston speeds, the double to more moderate ones. Steel enters largely into their construction, being used for the shaft, rods, pins, and in every case where a gain can be made by employing it. The connecting-rod is extra large, constructed so that wear does not appreciably alter its length, and is disconnected very quickly. Care has been taken to ensure thorough oiling of the locomotive style of cross-head, it traveling in a recess in the frame which contains oil at all times. There has also been provided an adjustable cross-head gib, faced with babbitt, thus giving perfect alignment. The piston - rod is securely locked in the cross-head by a fine thread and jam nut, and travels through a babbitted gland.

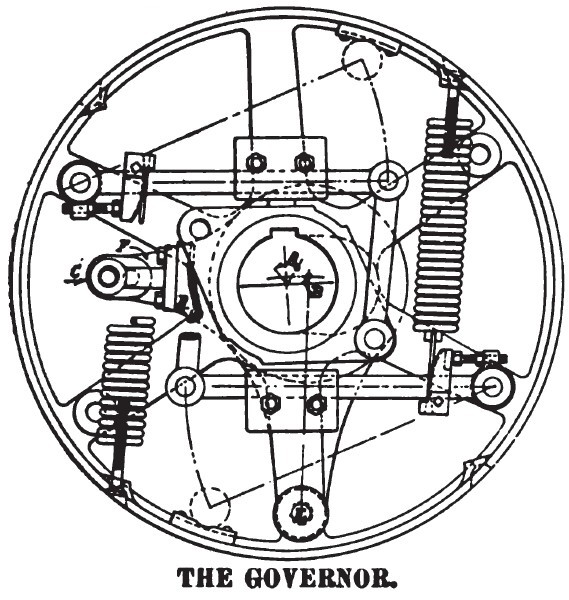

The valve applied to the design shown in the cut is balanced by an extra heavy pressure plate and two distance pieces, is so constructed that steam is admitted to the cylinder by four different openings at once, and exhausted by two passages. By these means wire-drawing of the steam is prevented and a very free exhaust obtained. Provision has also been made by which any wear which occurs can be remedied, and as the clearance has been kept down, the valve will give a very economical use of steam. The ports are so situated that water which enters the cylinder passes immediately into the exhaust, and in extreme cases the valve itself can lift from the seat and thus give additional security against damage to the parts by water. Upon this page is shown in detail the governor employed in the single-valve design. The eccentric which controls the valve is centred at B, and swings across the shaft, being hung from the pivot E. There is a second eccentric centred at fitting snugly upon the hub of the governor case, as is shown in the sectional drawing. This eccentric is swung around the hub by means of the links and weight arms, as is shown in the elevation. As A is connected to the main eccentric by the straps D, the rod C, and the arm F which is cast upon the side of the main eccentric, when A turns around the hub the main eccentric swings across the shaft, thus making the cut-off occur earlier in the stroke. One great advantage of this style of governor is that it locks itself in whatever position it may be, thus preventing racing, and giving close regulation; also, that the same governor can be used for running either over or under, with only a change in the location of moving parts. (Manufactured by Webster, Camp & Lane Machine Co., Akron, O.) |

|

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine (front view)

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine (front view)

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine Governor

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine Governor

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine (back view)

1890 Webster, Camp & Lane Machine Co., High Speed Steam Engine (back view)

|

|