|

Title: |

1903 Article-Fosdick Machine Tool Co., Radial Drill |

|

Source: |

American Engineer & Railroad Journal Sep 1903 pg 341 |

|

Insert Date: |

3/18/2011 7:47:42 PM |

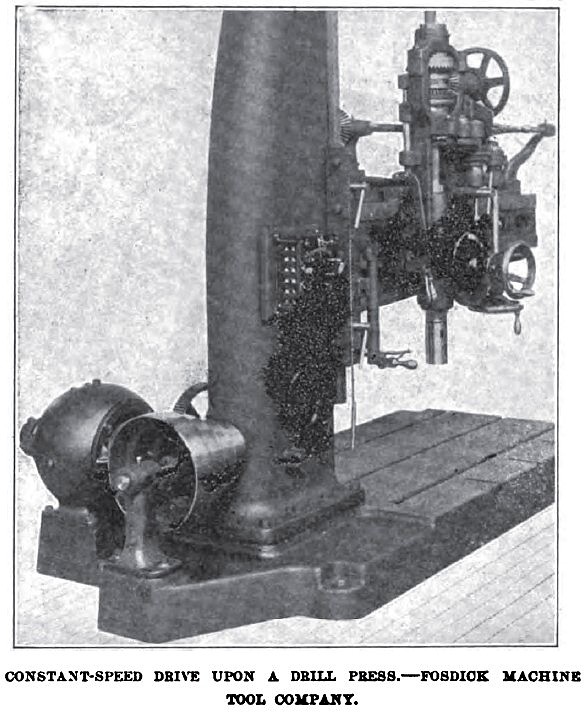

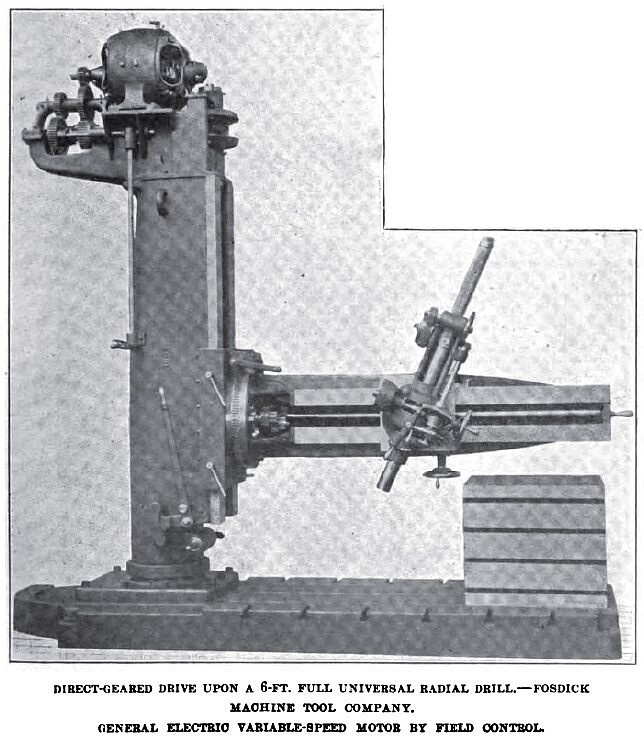

The two engravings presented upon this page illustrate the methods of mounting both variable speed and constant-speed drives, which have successfully been made use of by the Fosdick Machine Tool Company, Cincinnati, Ohio. These examples will take their place as the best practice in motor applications to this class of tools, the variable-speed drive being especially commendable. The larger engraving represents a 6 ft. full-universal Fosdick radial which has been adapted for a variable-speed motor drive. The result is an exceedingly neat drive, inasmuch as the use of all cone pulleys and belts is entirely obviated; it not only greatly simplifies the construction and operation of the drill, but also adds greatly to its general appearance. Cone pulleys and belts are rendered unnecessary by the use of the variable-speed motor, which is a 3-h.p. General Electric multipolar motor operating with field control.

In addition to the range of speeds provided in the motor two speed-changes are also obtained by means of two gear trains adjacent to the motor pinion. Either one is thrown into action by a friction clutch operated by the lever shown below on the column. The other interesting features of this universal drill are in no way interfered with, the most noticeable effect of the change being the absence of the cone pulleys and belts and the necessary accompanying supports, brackets, belt shifters, etc.

In the upper engraving is shown the method used by the Fosdick Company in applying a constant-speed drive. The machine shown is one of the 4-ft. plain Fosdick radials, which has been equipped with a 3-h.p. constant-speed, direct-current motor built by the Northern Electrical Manufacturing Company, Madison. Wis. This is a very convenient arrangement of adapting an individual drive to an existing tool without changing it greatly, as the motor may easily be mounted to drive the lower cone pulley through a conveniently arranged gear reduction. In this case the motor is mounted upon an extension of the base plate, and drives the lower cone shaft through bevel gears within the column. |

|

1903 Fosdick Machine Tool Co., 4' Radial Drill

1903 Fosdick Machine Tool Co., 4' Radial Drill

1903 Fosdick Machine Tool Co., 6' Radial Drill

1903 Fosdick Machine Tool Co., 6' Radial Drill

|

|