|

Title: |

1903 Article-Fosdick Machine Tool Co., Radial Drill |

|

Source: |

American Engineer & Railroad Journal Jul 1903 pg 272 |

|

Insert Date: |

3/18/2011 7:36:17 PM |

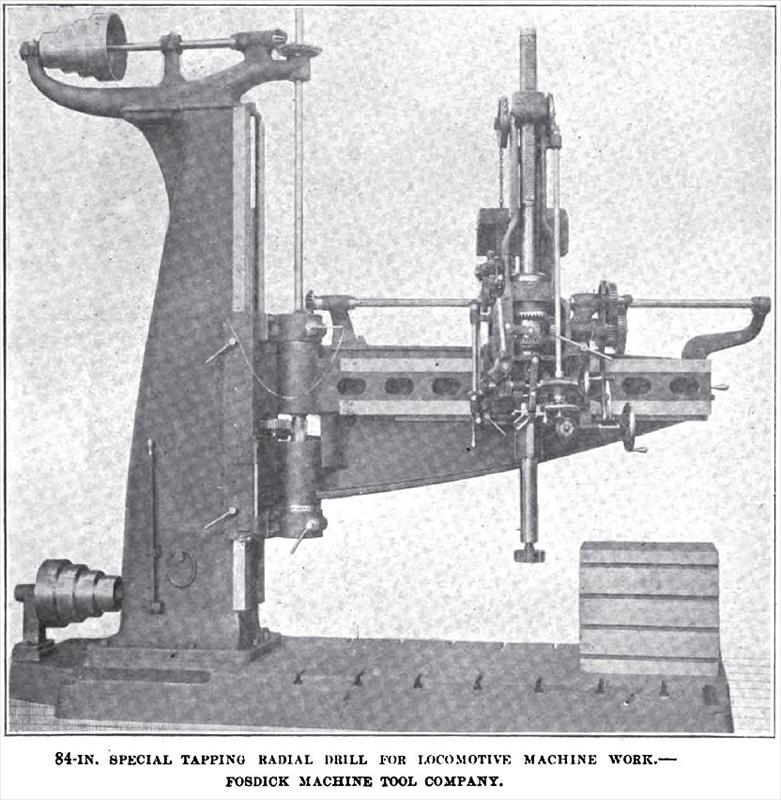

The accompanying engraving is an illustration of a new type of 7-ft. special tapping radial drill, which has recently been designed by the Fosdick Machine Tool Company, Cincinnati, Ohio. It embodies a particularly heavy and rigid design, being intended to meet the special requirements of locomotive builders, railroad repair shops and other large shops in boring cylinders, drilling, reaming and tapping large holes, etc. One of the distinctly new features of this tool is that it has a positive thread-cutting attachment for 8, 10, 12 and 14 threads per inch for heavy tapping. The tapping attachment is of a special design, constructed of hardened tool steel teeth clutches. The tool has also a variable-speed feed device, giving four drilling feeds, varying from .014 to .0079 per revolution. The spindle is 3-15-16 ins. in diameter, and has 30 ins. traverse. These features mane it possible to take care of certain classes of large work, heavy drilling, tapping, etc., to much better advantage than is possible on the plain radial drill.

The gearing used upon this drill is of steel throughout, all bevel gears being planed from the solid. An important feature is that the thrusts of the arm, of the spindle and of the elevating screw are taken by ball thrust bearings. The improved quick return used upon the head permits of engaging the power feed instantly.

SPECIFICATIONS.

Drills to center of circles of diameter 172 ins.

Greatest distance from spindle to base 90 ins.

Traverse of spindle 30 ins.

Traverse of saddle 65 ins.

Traverse of head on arm 57 ins.

Table 24 x 27 ins.

Height of drill 13 ft.

Total height with arm raised 18 ft. 6 ins.

Floor space 14 ft. 1 In. x 17 ft. 4 Ins.

Weight net 20,000 lbs. |

|

1903 Fosdick Machine Tool Co., Radial Drill

1903 Fosdick Machine Tool Co., Radial Drill

|

|