|

Title: |

1898 Article-Flickinger Iron Works-Sensitive Drill |

|

Source: |

Iron Trade Review, V31, 13 Jan., 1898, pg. 17 |

|

Insert Date: |

1/14/2025 9:50:09 PM |

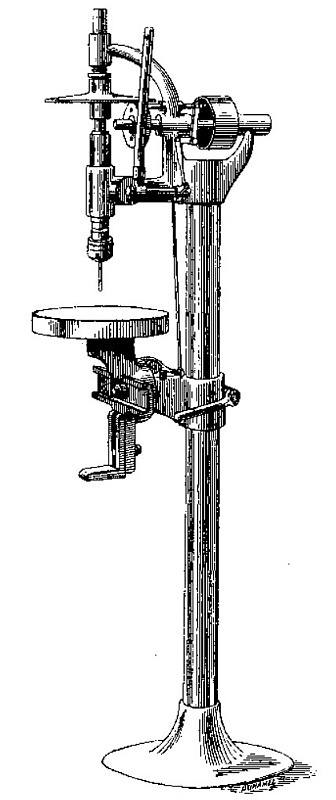

An improved sensitive drill has been patented and is manufactured by the W. W. Flickinger Iron Works, of Cochranton, Pa. The accompanying cut, with a few details of description, will indicate its construction and its service. It drills holes up to 5/16 inch diameter. The distance from the column to the center of the spindle is 8 inches; greatest distance from the spindle to the table, 30 inches. Traverse of spindle, 2¾ inches; diameter of spindle, 7/8 inch. The table has a diameter of 11½ inches, and the driving pulley is 5 inches in diameter, with 2 inch face. The total height of the machine is 66 inches and its weight 240 lbs. A gang of these drills can be belted from a single counter-shaft, using quarter-turn belts.

The feed lever operates the whole machine, including starting, stopping, increasing and diminishing the speed, and feeding. When the lever is pulled in the direction of feeding the spindle starts automatically. When it is raised to its standing position the spindle stops automatically, so the drill only runs when in use. The lever is simply moved to the right or to the left to increase or diminish the speed, which can be done at any time when drilling. The drill is provided with a turret table composed of a spider swiveled vertically on the platen arm, with four arms on which to place the different tables, chucks or jigs to hold the work. This is useful for duplicate work. The turret can be instantly revolved from one arm to another by pressing the stop. Rapid center drilling can be done on this drill with a combination center drill and reamer, as the speed can be instantly decreased when the reamer strikes the work. All small parts are of steel, including the rack and pinion, which have 34 inch face. The column is of cast iron. The horizontal shaft runs in babbitt metal boxes. The spindle also runs in babbitt through the quill seven inches long, with ball-bearing thrust. The upper bearing of the spindle is supported by a metal bush running in the bearing, preventing any wear on the spindle except the sliding movement. It also prevents the keyway from cutting the journal. The spindle is counterbalanced by means of a spring. The platen is also counterbalanced by a weight in the hollow column.

US Patent: 595,850

https://www.datamp.org/patents/displayPatent.php?number=595850&typeCode=0 |

|

1898 Flickinger Iron Works-Sensitive Drill

1898 Flickinger Iron Works-Sensitive Drill

|

|