|

Title: |

1911 Article-Webster & Bennett, Two-Spindle Drilling Machine |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pgs. 15-18 |

|

Insert Date: |

4/17/2020 1:22:57 PM |

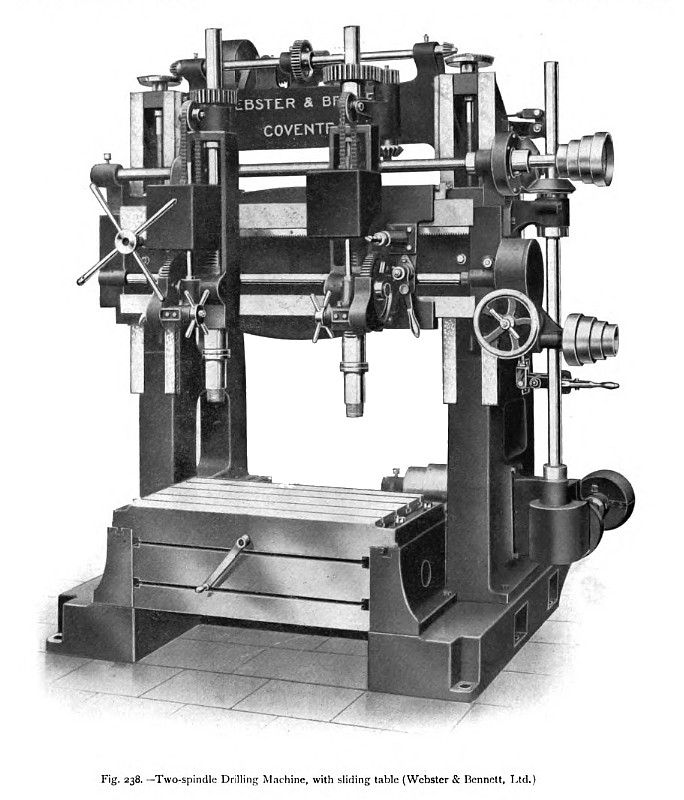

Another machine of a similar type, but adapted for a larger range of work, is illustrated in fig. 238, which represents a two-spindle drill made by Webster & Bennett, Ltd., of Coventry. In this machine the cross rail carrying the sliding heads is mounted upon machined guides on the two uprights of the frame and is capable of being raised or lowered by power to suit the work. In addition, the table to which the work is secured can be moved transversely under the drills by a worm and twin rack gearing operated from the front or the back. One large cone pulley at the back of the machine drives both spindles, which are controlled separately, and the automatic feed is also belt-driven. Both spindles may be fed together or independently, and a hand feed is provided for facing and recessing operations. Ten spindle speeds are obtained by means of the five-step cone pulley in conjunction with double back gearing, and a series of four feed rates is provided. In the machine illustrated the minimum spacing of the spindles is 6 in. and the maximum 39 in. Between the columns the clear space is 49 in. and maximum distance from the table to the spindle nose is 36 in.

Four-spindle machines of the same general form are constructed with double driving arrangements, the spindles being run in pairs at different speeds, suitable for boring, tapping, and other operations. |

|

1911 Webster & Bennett, Two-Spindle Drilling Machine

1911 Webster & Bennett, Two-Spindle Drilling Machine

|

|