|

Title: |

1875 Article-Bradley Mfg. Co., Cushioned Helve Hammer |

|

Source: |

The Masterpieces of the Centennial International Exhibition Illustrated, V3, 1875, pg. 113 |

|

Insert Date: |

3/7/2019 8:14:24 PM |

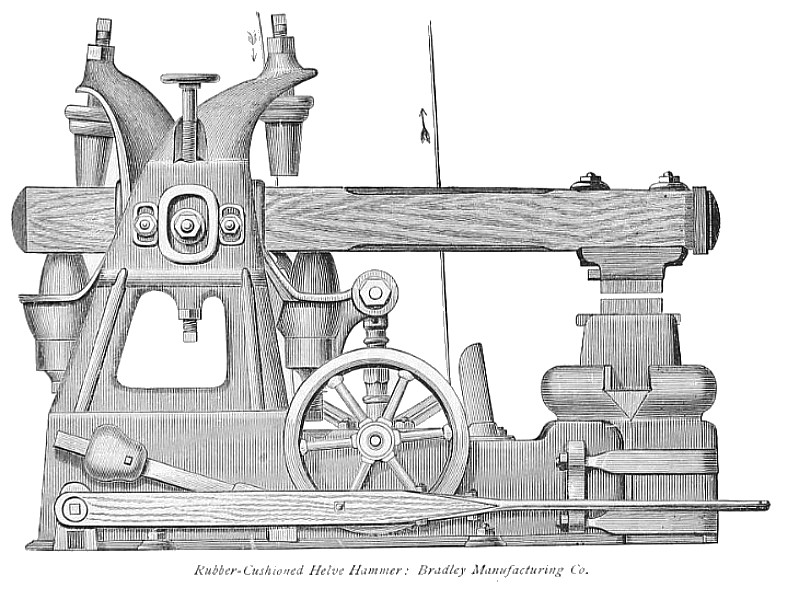

The trip or helved hammer approaches nearer to the hand-hammer in its action than any other mechanical agent of its class, and for this reason is better adapted to certain peculiar kinds of work. There have been various causes, however, operating against its use, one being the difficulty of making proper connection with the driving power. The sudden shocks which it produces on shafting in starting, the irregular motion and the varying power required, all prevent the use of rigid connections, necessitate the adaptation of slipping belts, and require strict application of the principles of elasticity in the entire construction of the machine. Even with all this, the wear and tear in the ordinary hammers, as usually built, is far beyond what occurs with other machines, tending to counteract any inherent advantages that this special form may possess. The Bradley Manufacturing Company, of Syracuse, New York, has placed on exhibition one of its Rubber-Cushioned Helve-Hammers, represented by the engraving, on page 113, which it claims possesses great advantages and improvements over any other hammer of its kind in use. With the exception of the helve, which is of wood, the entire hammer, is constructed of iron and steel, so proportioned as to dispose of the material to the best possible advantage. The helve is hung upon two hardened adjustable steel centres and almost perfectly balanced, motion being given to it by a broad eccentric with an iron hub, a bronze shell and a cast-steel strap, all so perfectly fitted as to reduce friction to a minimum and to allow complete adjustment.

Rubber cushions are provided and so arranged as to absorb the concussion of the blow of the hammer and materially decrease the strain and jar which ordinarily obtains. Set screws in the upper and lower sockets of the oscillator allow of adjustment to these cushions. The bearings throughout are of the best quality anti-friction metal, except those of the main shaft, which are of bronze; an adjustable eccentric is used, easily regulating the length of stroke required, and a universal joint connection prevents the possibility of binding or heating. By the method adopted of raising and lowering the husk, dies varying an inch in thickness may be used without shimming up either end, thus preserving the key-ways and hammer bolts. In securing the hammer-head to the helve, rubber cushions are used beneath the nuts and collars of the bolts,absorbing all concussion, preventing loosening or breakage and increasing the elasticity and flexibility of the blow. A foot treadle around the bed of the hammer allows the operator to stand in front or on either side and by a gentle pressure bring the tightener in connection with the belt on the drive-pulley, varying the stroke as desired. On removing the pressure, the brake acts at once on the balance-wheel and the hammer is brought to a stop instantly, with the helve always up. The action is the nearest approach to that of the human arm that it seems possible to obtain, being accurate and powerful, perfectly adjustable in length of stroke, rapidity of motion and weight or force of blow, and entirely under the control of the operator. Water, steam, or any other power may be applied.

It is claimed that not more than half the power is required to do a given amount of work that is necessary in the direct steam hammer. There is no liability to corrosion of steam chest, sticking of valves or freezing and bursting of pipes in winter from nonuse. For intermittent use it is exceedingly well adapted, always responding to the touch of the treadle, be it once per day or once per week. Its drawing capacity and accuracy of stroke give it great advantages over the vertical or dead-stroke hammer. The play required in the guides or ways of the latter for expansion of the ram under heating, allowing it to run loose enough to shuckle, is fatal to nice die swedging. In this hammer, the centres being away from all heat, it strikes equally well whether the head is expanded or not. It is claimed that as a drawing hammer it has no superior, and it is under such perfect control that a block of iron three inches square may be reduced to one-eighth inch square under the one hundred-pound hammer without adjustment. A simple device allows adjustment from one power to another, as from a sixty pound to a forty-pound hammer, in a few minutes. It is claimed that no hammer in use possesses the elasticity of stroke which this does. Objection is sometimes made to helve hammers because they do not strike perfectly square on different thicknesses of work, but this is obviated in the construction of the dies, and in swedging it gives no trouble. |

|

1875 Bradley Mfg. Co., Cushioned Helve Hammer

1875 Bradley Mfg. Co., Cushioned Helve Hammer

|

|