|

Title: |

1870 Article-Tanite Co.-Saw Gummer Grinder |

|

Source: |

American Artisan, V10, 16 Mar 1870, pg. 164 |

|

Insert Date: |

11/28/2018 4:44:13 PM |

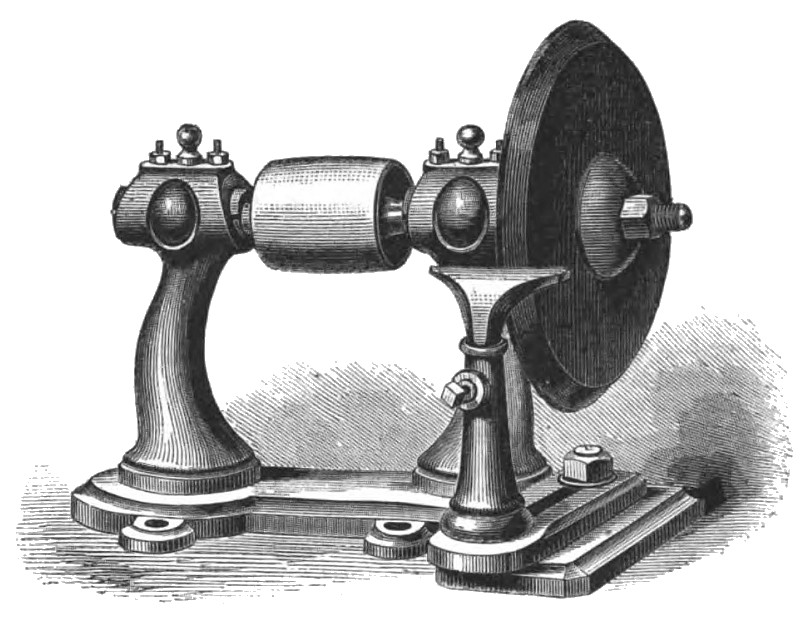

PATENT FLANGES FOR TANITE WHEELS For SAW-GUMMERS, ETC.

The abrading material, tanite—a compound of emery with other-materials to bring it to the requisite consistence for molding into shape—is found to subserve a superior purpose in the various uses for which ordinary emery-wheels are employed. In the accompanying engravings are represented two applications, or rather adaptations, of the substance. One of these, represented in Fig. 1, constitutes an improved saw gummer; Figs. 2 and 3 represent a means of holding annular wheels in place, whereby the disadvantages incident to solid wheels are avoided—Fig. 2 being a transverse sectional view of the wheel and its attached flanges, and Fig. 3 a detached view of one of the latter. With reference to the saw-gummer, it is designed to supply a want not previously fully met, of an apparatus for gumming saws, which would be at once moderate in price and effective in operation. Some of those hitherto in use have sold at one hundred dollars each and thereabouts, while those of less price are said to have been proportionally inefficient; the more expensive machines, further. more, occupying more space than can be conveniently accorded in the manipulation of such mechanism, and also very frequently so complicated as to require more than ordinary skill to keep them in repair and working order. The machine herewith illustrated has claimed for it no special originality. The advantages specified in its behalf are, that it is compact and of small size, that it is strong and durable, that it is so arranged that the emery-wheel used can be worn down to a small diameter without danger of the saw-teeth striking the nuts, flanges, or oil-cups, and, lastly, that its price puts it within the reach of all. The most noticeable feature in this machine is the shape of the standards, and the compactness of arrangement in the bearings and boxes. These boxes are free from all projecting points and angles, the flanges to the wheel are made thin, and every precaution is taken to prevent the occurrence of that frequent accident in saw-gumming—the striking of the saw-teeth upon some part of the machine. By such an accident the saw-teeth are sometimes broken, and sometimes the tooth strikes the flange-nut and loosens it so that the emery-wheel flies off. Emery-wheels are rapidly superseding the grindstone and file in all cases where saws have to be gummed. One objection is raised against them, however, on which a word of explanation is needed. It is said that solid emery-wheels case-harden the saw, so that a file will not touch it! By the time the last cut back is given by the wheel to the saw the first teeth cut will be cool again. If the work. man will then go over the saw a second time, just touching his wheel between each tooth in the lightest manner, he will break the scale, which is only surface deep, and then the file can be easily used for finishing.

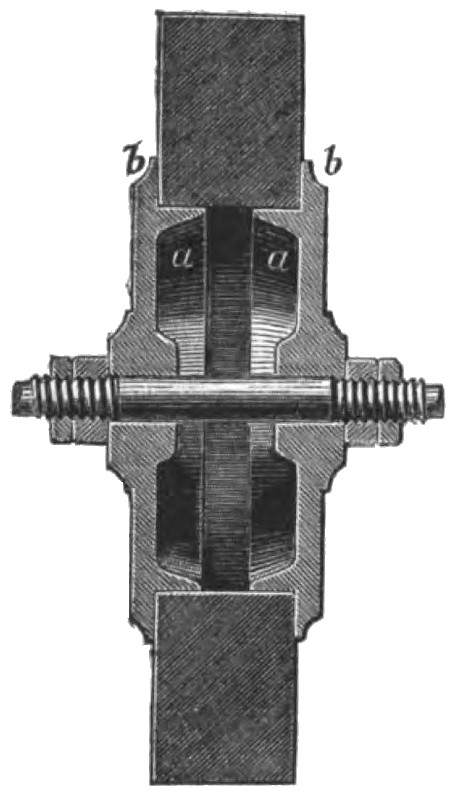

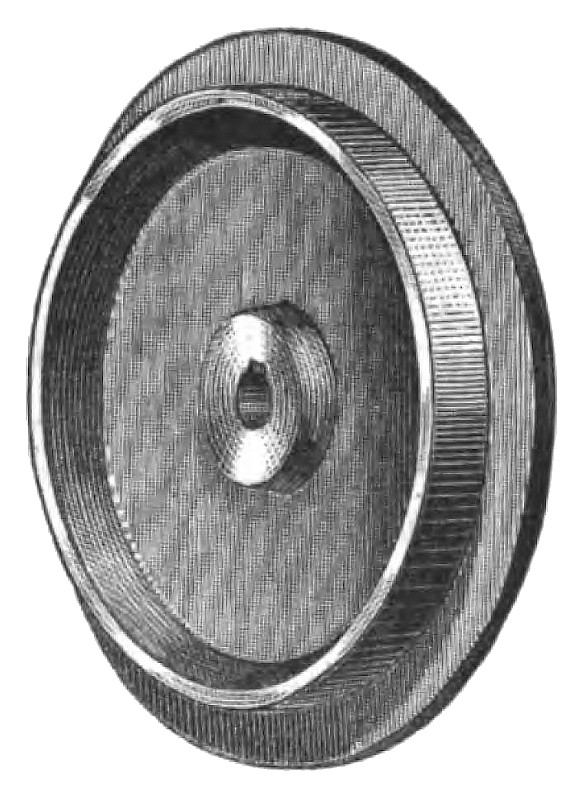

As previously indicated, Figs. 2 and 3 relate to an improved method of forming or fitting-up an emery-wheel. The essential feature of the plan will be seen by a reference to the engravings, the annular wheel being sustained concentric to the axis of motion by the two annular shoulders, a, on the supporting flanges, while the lateral displacement of the wheel is prevented by the rims or edges of the flanges, which clasp it on either side, as shown at b.

The flanges represented above are of value in all cases where it is desired to use an emery-wheel of large diameter, without having the considerable weight of a solid wheel, and without the constantly lessening diameter of such solid wheel. One of the objections brought against this last-mentioned kind of emery-wheels, in comparing them with the old wood and leather wheel, has been that the wooden wheel always keeps up its full diameter, while the steadily decreasing diameter of a solid wheel gives a decreasing speed and an altering arc, and leaves a useless supply of solid centers on hand. To obviate this defect, emery-wheels have been made in rims; a wheel being made, for instance, of 16 inches diameter, and of any desired thickness, but with a hollow center of 8- or 10-inches diameter. The object of the improved flanges is to run such wheels or rims. Hitherto the hollow center has had to be filled with wood, and as only a wooden center perfectly made would answer, no machinist could use such wheels without going to a pattern - maker for his center. A favorite plan with those desiring to economize has been to have solid wheels molded on to iron centers or hubs. Not to speak of the certain danger of this plan, resulting from unequal expansion and contraction of the metal and the compound, the iron hub had to be sent by express, back and forth, whenever a new wheel was needed. The improved flanges, once bought, can always be retained, and wheels furnished which are exactly fitted to them, thus serving to hold the wheel tightly and center it with great accuracy.

A patent on these flanges has been allowed to the Tanite Company, of Stroudsburg, Pa., and will issue in two weeks. The saw-gummers and tanite wheels with improved flanges are manufactured and for sale by the Tanite Company (T. Duncan Paret, President), Stroudsburg, Pa., to whom all orders or inquiries for further information should be addressed.

US Patent: 101,058

http://www.datamp.org/patents/displayPatent.php?number=101058&typeCode=0 |

|

1870 Tanite Co.-Saw Gummer Grinder

1870 Tanite Co.-Saw Gummer Grinder

1870 Tanite Co.-Saw Gummer Grinder Flange (Sectional View)

1870 Tanite Co.-Saw Gummer Grinder Flange (Sectional View)

1870 Tanite Co.-Saw Gummer Grinder Flange

1870 Tanite Co.-Saw Gummer Grinder Flange

|

|