|

Title: |

1908 Article-Merrill Bros., Drop Hammer |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 23 |

|

Insert Date: |

11/7/2017 9:50:26 PM |

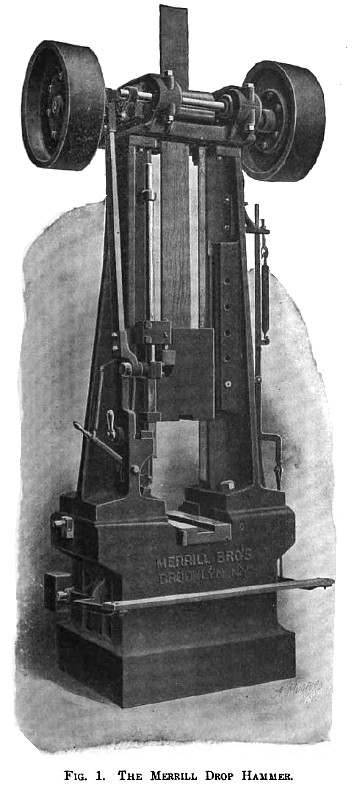

The drop hammer shown in Fig. 1 embodies all the improvements which Merrill Bros., Brooklyn, N. Y., have found to be most efficient during their thirty years' experience in the use and manufacture of this machine. The principal improvement consists in the lifting device, which they claim to be the simplest and most effective yet offered. In addition to this, the size of the uprights has lately been increased and the base widened to correspond, thus producing a more stable machine and better maintaining the alignment. All the hammers are regularly fitted with an automatic attachment by means of which a succession of blows can be struck without raising the foot from the treadle. Suitable arrangements are made for readily disengaging this automatic attachment and the operator can then strike either a light or a heavy blow at will, the hammer striking only when the treadle is moved. Every machine is erected and tested before being shipped. The weight of the ram, the height of the uprights and the distance between them, can be varied to suit the purchaser, at a slight additional cost.

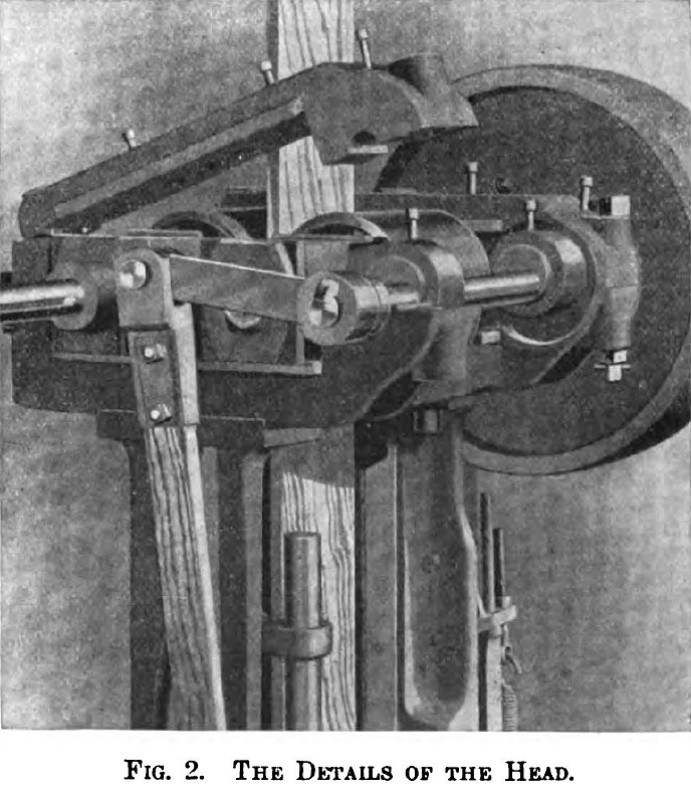

In the new head or lifter, Fig. 2, the brass eccentrics formerly used have been discarded, and a forged steel cam shaft has been substituted, which is fixed solidly at both ends into the head casting, and connected to a wooden rod. This straight wooden rod entirely prevents any shock being received by the lifter.

The friction roll shafts are Babbitted into sliding boxes. The front boxes are connected by links to the steel cam shaft, which, when rotated through a small angle, moves the front roll in a horizontal direction, to and from the lifting board attached to the ram. In use, the rear roll boxes are stationary, but can be adjusted horizontally to compensate for wear on the board. By this arrangement of sliding boxes and horizontal motion, the movable roll advances in line with the center of the opposite fixed roll, insuring the pressure of each roll against the lifting board, being directly opposite. It is furthermore claimed by the manufacturers that in case the friction rolls should not be properly adjusted, it is impossible for the rod to fall far enough to allow the cam to pass beyond the center, thereby causing the rolls to bind and throw off the belts. If desired, lifters will be furnished with the clamp device to suspend the hammer by clamping the friction board instead of resting on the side latch. The lifting board is fastened in the hammer by means of wedges, which permit the use of straight boards as received from planing mill and without further preparation.

These hammers are built in a number of sizes to suit various conditions of work and each one is furnished with two paper pulleys. |

|

1908 Merrill Bros., Drop Hammer

1908 Merrill Bros., Drop Hammer

1908 Merrill Bros., Drop Hammer (Details of Head)

1908 Merrill Bros., Drop Hammer (Details of Head)

|

|