|

Title: |

1921 Article-Van Dorn Electric Tool Co., Heavy Duty Grinding Machine |

|

Source: |

Machinery, V28, Oct 1921, pg. 154 |

|

Insert Date: |

5/7/2019 8:47:55 AM |

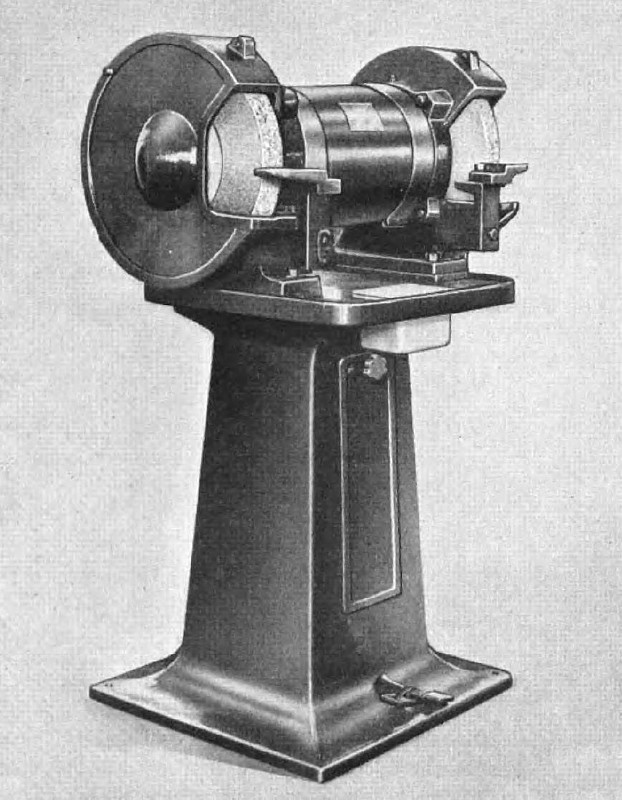

The heavy-duty ball-bearing grinding machine here illustrated has just been introduced to the trade by the Van Dorn Electric Tool Co., Cleveland, Ohio. It is equipped with two grinding wheels, 14 inches in diameter, and 2½ inches face width. These wheels are mounted directly on the ends of a 1¼-lnch motor shaft, and they are quickly changed by removing four bolts and the end flanges. Provision is made on the wheel guards for connection with exhaust ducts when desired, and a lug on each guard permits an eye-shield to be attached. The tool-rest can be conveniently located by horizontal and vertical adjustments. An aluminum water pot is located in the proper position to be reached by a short movement of the arm. This pot may be readily lifted out of place.

The motor was designed especially for this machine, and its rating is 4 horsepower for normal continuous operation, and 7 horsepower for a momentary overload. The standard motors operate on three-phase. 60-cycle alternating current with either 220 or 440 volts, but special windings such as two-phase 60-cycles, or three-phase 50-cycles, with either of the given voltages, are made to special order. The speed of the 60-cycle motors is 1200 revolutions per minute, and that of the 50-cycle motor, 1500 revolutions per minute. The motor is completely enclosed by a dustproof housing which is smaller in diameter than the grinding wheels, so that there is ample space for the operator's hands to move without coming in contact with the machine. Interference when grinding long pieces is also obviated.

Ventilation under all normal conditions is furnished by a fan within the motor, but under conditions of excessive dust a supply of fresh air may be piped to the intake of the housing. The motor shaft is set in large ball bearings rigidly supported by the housing. Lubrication is accomplished by inserting a grease-gun nozzle in grease ports located directly above the bearings. The pedestal serves as a cabinet for the switch, fuses and connections. The cable conduit enters through a hole at the back, and no wires or electrical appliances are exposed anywhere on the machine. The machine is started and stopped by a pedal switch located at the base of the pedestal. The spindle center is 39 inches above the floor, and the grinding wheels are set 25 inches apart. The machine weighs approximately 700 pounds. |

|

1921 Van Dorn Electric Tool Co., Heavy Duty Grinding Machine

1921 Van Dorn Electric Tool Co., Heavy Duty Grinding Machine

|

|