|

Title: |

1908 Article-John B. Morris Machine Tool Co., 18 in. Plain Change Gear Schellenbach Lathe |

|

Source: |

Iron Age, V82, 01 Oct 1908, pg. 1071 |

|

Insert Date: |

2/18/2016 9:27:10 PM |

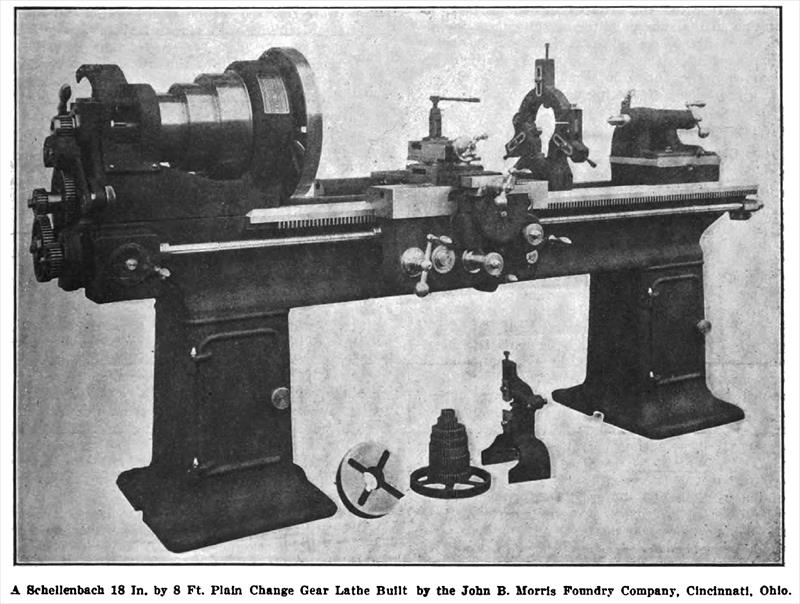

All the features of the Schellenbach cone head machine illustrated in The Iron Age, October 1, 1908, except the quick change device for cutting threads, are found in the new 18 in. x 8 ft. plain change gear lathe herewith illustrated and built by the John B. Morris Foundry Company, Cincinnati, Ohio.

With the set of 11 change gears provided all standard threads from 2 to 72 per inch can be cut. The feed box is bolted to the bed, and affords three changes of feed for each change gear. When the machine is geared for the finest pitch, the carriage is fed at 0.005, 0.009 and 0.014 in. per revolution of the spindle. This feed change is made through the crank shown on the front face of the speed box below the headstock. A quadrant is fitted to the feed box, and is clamped to it by two screws. The latter and all other adjusting screws on the machine fit the tool post wrench. The change gears are secured to the stud and screw by slip washers, making it unnecessary to remove the nuts when changing the gears. When the crank shown on the face of the speed box is to the right, the clutch connects the lead screw directly with the change gear stem, and the other two positions for this crank connect sliding gears which give two more feed changes.

This machine has a double apron, which includes mechanism for rough chasing all threads without the use of the lead screw. The back gear speeds drive directly to the face plate or chuck, and the highest ratio is 17 to 1. The largest step of the cone pulley is 12 in. in diameter by 3-in. face. This machine is also manufactured in 14 and 16 in. sizes. |

|

1908 John B. Morris Machine Tool Co., 18 in. Plain Change Gear Schellenbach Lathe

1908 John B. Morris Machine Tool Co., 18 in. Plain Change Gear Schellenbach Lathe

|

|