Edward P. Allis and His Life Work

It is now forty years since Charles S. Decker and James Saville, two young men from Dayton, Ohio, came to Milwaukee and laid the foundation of what has since become the "Reliance Works" of Edward P. Allis & Co. The germ of the present immense works, as planted by the firm of Decker & Saville, consisted of a small stove foundry and a small machine shop. The works were located on the east side of what is now West Water street, a short distance above the present Oneida Street bridge, and had a millstone shop in which was manufactured the first pair of millstones ever made west of Lake Michigan. Small as the shops were at that time, they were the largest of the kind west of Buffalo, and the only ones where a full set of mill irons could be obtained. The buildings, which were wooden structures, stood upon leased ground, and the motive power was furnished by an eight inch cylinder engine. Concerning this engine, Mr. Frank Brunckhorst of Kewaunee, Wisconsin, who entered the Reliance works as draughtsman in 1854, writes, in 1885, that it was still running at that time and furnishing the power to drive a small saw-mill some nine miles west of Kewaunee. Although the institution was a small one, it proved to be too much of an elephant for the owners and they went to the wall during the hard times of 1857. The creditors took the works in hand, and they were run until 1860 under the management of Samuel S. Daggett, when they were purchased by Edward P. Allis, John P. McGregor and Charles D. Nash. The new owners soon found that more capital was need; in consequence Mr. Allis purchased the other interests.

At the time (1861) when Mr. Allis purchased the business it consisted of general repairing and odd jobs. No attempt had ever been made to develop any line of systematic manufacture. During the administration of Mr. Daggett the annual business done amounted to thirty-one thousand dollars. After four years Mr. Allis more than trebled the volume of the business. During this time and for some years afterward he personally discharged all the duties of salesman, bookkeeper, correspondent and paymaster, the last being often the most difficult. The mechanical department was entrusted to Mr. A. G. Waldo, a good mechanic, who had entered the works while they were still under the ownership of Decker & Savilie, and who remained in charge of the works as foreman until his death, a few years after Mr. Allis became sole proprietor.

Allis maintained a policy of keeping the shops full of work and the men busy, no matter how small the margin of profit. The first important contract, and one which was undertaken solely on this policy, was that for furnishing the cast-iron chairs on which the rails of the old La Crosse railway first rested. The price realized was but barely above the price of the iron in the pig, but it kept the men employed. The first important machinery contract undertaken was that for the machinery for the first grain elevator built in Milwaukee. During all the years up to the present time this policy has been maintained.

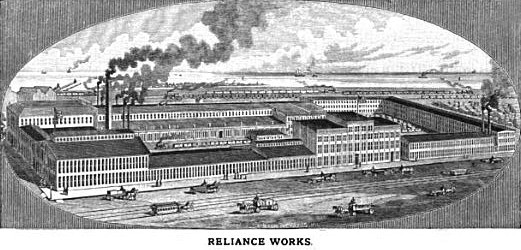

The original Reliance Works on West Water street soon became too small for the increasing requirements of the business, and in 1865 Mr. Allis purchased the present site and the new Reliance Works were built. The site chosen consisted of the three blocks lying between Clinton and Barclay streets and reaching from Florida street on the north to Pierce street on the south. The old buildings were floated down the river on barges from West Water street, and put to subordinate uses in the new plant. Up to a year ago, some parts, rebuilt, remodeled and altered so as to be unrecognizable, were still in use, but the improvements of the present year have left little if any remaining. In addition to the old buildings a new machine shop and foundry were built. The former was erected on the southeast corner of Florida and Clinton streets, 60 x 140 feet, two stories high, with an attic or pattern loft under the roof. The foundry adjoined it on the east, but after a few years a larger foundry was built on the Barclay street side and the old foundry was used as part of the erecting shop. During the present summer (1887) it has been entirely torn out, and a brick building erected in its stead. The machine shop built in 1865 is still standing and in use, the first floor as a part of the machine shop and the second floor as a pattern shop. The motive power of the works at this time—1865—was a fifteen horsepower Ames portable engine, to which was soon added one of twenty-five horsepower, the pair running either singly or together as the necessities of the works required. At present over four hundred horsepower are required to drive the vast and complex mass of machinery contained within the works.

Business was so prosperous in the new location that four years later, in 1869, Mr. Allis purchased the Bay State works of Walton & Goodnow. In the early days of Milwaukee one William Goodnow started a little machine shop and foundry on the northwest corner of Florida and Clinton streets. He was meeting with fair success, but when the Reliance works were located diagonally across from him, he, in a spirit of business rivalry, projected the Bay State shops, his design being to have the best and most completely equipped machine shop in the west. He accordingly purchased from John S. Harris the ground on the southeast corner of Lake' and Barclay streets and put up a three-story brick building, with engine-room, foundry and blacksmith shop adjoining. The whole establishment was equipped with an extensive outfit of tools, patterns, etc. The plant was, however, far in advance of legitimate trade requirements at that time, and the owners became heavily involved and finally hopelessly bankrupt. After various unsuccessful attempts to continue the business by receivers and assignees, the works were finally sold to Mr. Allis, who purchased the property as a speculative investment. The Bay State works stood idle for several years, and were then leased to the Chicago, Milwaukee & St. Paul Railway Company for a time, and were used as the company's repair shops. At the expiration of the lease the works were refitted throughout and have since been operated in connection with the main works and under the same management.

In 1872 a department for the manufacture of cast-iron water pipe was added to the Reliance works, but it did not prove peculiarly successful and after a few years was abandoned, as it was found that the foundry could be made more profitable in other lines of work. The business, in common with all others, suffered during the dull times from 1873 to 1879. Since 1880 the growth of business and with it the growth of the works as a whole, has been phenomenal, and at the present writing this growth shows no signs of weakening.

Several distinct lines of manufacture are followed, in addition to which the works enjoy probably the largest jobbing and repair trade in the west. The firm of Edward P. Allis & Company stands preeminent in the manufacture of steam engines, flour mill machinery and saw-mill machinery, and is rapidly building an enviable reputation in mining machinery, heavy pumping engines and other lines. Flouring mill work, which has of late years become one of the most important portions of the annual out put of the works, was in the early days, when Mr. Allis first took possession, small in amount and was done entirely after plans furnished by local millwrights. The mill furnishing work at that time was unsatisfactory to Mr. Allis and he was, therefore, constantly on the lookout for some specialty upon which he could improve the works. He had early secured the agency for the northwest for the Leffel water-wheel, which was rapidly displacing the overshot and primitive turbine wheels made by the Reliance works during their first few years' existence. This agency was one of Mr. Allis' fortunate hits and had much to do with placing the works on a permanent foundation. Over six hundred Leffel water wheels were sold in one year. The manufacture of mill stones was also increased, to over three hundred runs per year. By bout 1872 the art of milling began to undergo radical change. Allis engaged Mr. W. D. Gray, now one of the most widely known milling engineers, as chief of the mill furnishing department, and sent him to Europe to learn all that could be learned of European practice which would benefit American millers. The result of his visit was the introduction and adoption of the gradual reduction system of roller -milling in this country, the first complete roller mill in this country, called the Washburn Experimental mill, having been built under Mr. Gray's direction. The establishment now turns out nearly everything in the line of machinery needed to equip the largest and most complete mills, including roller mills, centrifugal reels, purifiers and other machines too numerous to mention. Instead of following the plans of local millwrights, the work is now done from plans made at the works by competent engineers and draughtsmen, and everything is systematically designed and the work put as nearly as may be upon an exact scientific basis. As the result, the firm of Edward P. Allis & Company stands the head of the mill furnishing industry of this country, and the trade, both in the building of complete mills and in the furnishing of special machinery and supplies, is steadily increasing.

In 1877 Mr. Edwin Reynolds, who had for ten or twelve years been connected with the Corliss steam engine works at Providence, Rhode Island, came to Milwaukee and took charge of the Reliance works as general superintendent. Under his charge the manufacture of the Reynolds' Corliss engine was undertaken and has met with the most flattering success. Nearly one thousand are now in use, of sizes ranging from twenty horse-power up to twenty-five hundred horse-power. The sales have constantly increased, and the record for 1887 will double that of any previous year. Ten years ago the man who prophesied that New England manufacturers would come to Milwaukee to buy engines would have been laughed at for his pains; yet among the engines now building at the Reliance works, under Mr. Reynolds' supervision, are two large compound condensing and a two thousand horse-power quadruple expansion engine for New England cotton mills. Among the large work just completed are two twenty-five hundred horsepower engines and one of five hundred horse-power for the Edgar Thompson steel works at Pittsburgh, Pennsylvania, in which works are seven large blowing engines, also built by the Reliance works. Five large blowing engines are now building for Birmingham, Alabama. Among other work in the engine line built by the Reliance works may be mentioned the pumping engines at Milwaukee, St. Paul, Omaha, Allegheny City, Hannibal, Missouri, and Decatur, Illinois. The triple expansion engine recently put in position in the new high service station in Milwaukee, although in operation but a short time, has an unprecedented record for high duty.

As illustrating the general growth of the works, that of one department will be of interest. In the foundry, under the first five years of the present ownership, the daily "heats" or amount of iron melted were from one-half ton to three tons. In 1884 the output averaged over thirty tons per day. The sixth of January, 1887, the heat was over seventy-five tons. That night the first serious fire in the history of the Reliance works took place and the foundry was completely destroyed. Luckily, the favoring direction of the wind and the brick fire walls at either end of the foundry, together with the strong work of the city fire department, saved the balance of the establishment. Rebuilding is now completed and the foundry is again melting fifty to sixty tons per day, which capacity will be increased as may be necessary. In addition another foundry has been leased and is melting about fifteen tons per day, while hundreds of tons of heavy work have of necessity been ordered outside. It was also determined at the same time to rebuild and enlarge the erecting shop and separate it from the machine shop by fire walls. This necessitated the removal of the general offices, and as a result the building of a new section of the works. At the same time a large amount of new and heavy machinery was ordered. The summer's work has therefore been a busy one, over a quarter of a million dollars worth of improvements having been added to the works. At the same time the works have been even busier than usual in keeping up with the demands of the ever increasing trade.

Edward P. Allis, the son of Jere and Mary Allis, was born at Cazenovia, New York, May 12, 1824. He graduated from Union college, Schenectady, in 1845, his education having been with a view to the practice of law. However, his tastes favored an active business life, and in 1846 he located at Milwaukee, where in connection with William Allen he opened a leather store at what is now 344 East Water street. The firm of Allis & Allen continued till 1854, during which time it built a large tannery at Two Rivers, Wisconsin. In 1854 Mr. Allis sold out his interest in the firm and in connection with John P. McGregor engaged in the real estate and brokerage business. In 1861 he came into possession of the Reliance works, as already stated, and from that time forward his business history is written in the history of the works.